Over the last few year, we have seen the number of electric vehicles (EVs) increase.

Whilst the publicity is primarily around new, EVs which are chained to their manufacturer-branded workshops, it won’t be long before independent workshops are going to see out-of-warranty vehicles turning up for service or repair work. The largest part of the current EV fleet is actually used imports such as the Nissan Leaf.

What then, do New Zealand workshops need to do to be ready for this? Traditionally, its no small undertaking to upgrade a workshop, but being prepared for EV servicing? What shocks await?

We asked Gavin Young of Hyundai New Zealand – the distributor which is arguably one of the loudest voices when it comes to EVs – what workshops should be prepared for to deal with EVs.

“The first consideration is space,” opines Gavin, who estimates an EV needs about a metre and a half all the way round the vehicle in a closed off/barriered area to work on it. “You are going to be working with high voltage components,” he explains “and above all else, safety is the critical consideration in a workshop environment.”

So, is your shop able to accommodate working on an EV as well as working on standard vehicles?

There is also the consideration of EV charging stations and how much space they’ll require, plus any civil works issues – getting mains power to the charging location.

“We are still learning to crawl when it comes to EV servicing,” says Gavin, “and there are few hard and fixed guidelines. Most of our current best practice comes from parent companies overseas or from WorkSafe NZ, which is helpful, but gives very generic information.”

The next most critical consideration is the training of technicians. Here OEMs have a distinct advantage over independent workshops, who are likely to find this to be the biggest hurdle.

“When we – New Zealand – began importing second hand imported EV’s,” says Gavin, “there was no centralised knowledge bank to draw information on servicing and maintenance of those vehicles, so a lot of what we learned was self-taught.”

As an OEM distributor, training is part and parcel of day-to-day business. Hyundai techs were flown to Korea for a week’s worth of training, then worked alongside product planners to identify the vehicles being sold here. After this, it was a matter of training the technicians accordingly.

Even so, Gavin points out, it was only senior techs who were given the opportunity to qualify as EV master technicians – a certified or expert level tech was not going to cut it.

With some solid technical knowledge in place, Hyundai collaborated with MITO to develop a generic training syllabus, sharing information in order to give some form of training to non-OEM repair and service agents.

MITO’s training programme takes about 11 months to complete – which is quite a commitment.

Included in the course is a combination of theory and practical work, with the practical being the biggest insulated spanner in the works, due to the low number of EV’s requiring servicing and giving technicians little opportunity to complete the required hours working on them.

Not enough EV’s through the shop equals not enough hours to train. A solution of course, is for the shop to own an EV as a courtesy car, but it’s still a costly exercise for the sake of training.

But let’s assume the independent workshop wants to go ahead. What is their EV specialist going to learn?

“Most critically,” suggests Gavin, “will be the stress on safety. Setting up the barriers around the vehicles themselves, the importance of isolating high voltage systems – a simple matter of pulling the right fuse to isolate the high voltage components – having clear signage and the implementation of single technician mentality.”

To explain: this last is a favourite consideration of Gavin’s. One tech works on the vehicle and he/she is the only one working on that vehicle.

If the tech starts work and doesn’t complete it by the end of the day, no one touches that vehicle the morning after, say.

“If the tech who started the work calls in sick, the ‘lockdown’ – useful word – remains in place and nobody else touches the vehicle.

“This does mean changes in conventional workshop operation,” adds Gavin, “because in addition to the inability of other technicians to takeover, someone also has to keep an eye on the tech who was working on the EV to ensure nothing happens to him/her.

“John may be at the far end of the workshop with an isolated EV, but someone needs to make sure he’s alright from time to time, rather than John being unaccounted for, for an hour or so.”

And about an hour is what Gavin estimates a critical inspection/service should take for an EV. Yes, they don’t need as much time to service, but they DO have to be serviced. And interestingly, they need to be serviced at the same sort of intervals as an ICE (internal combustion engine) vehicle.

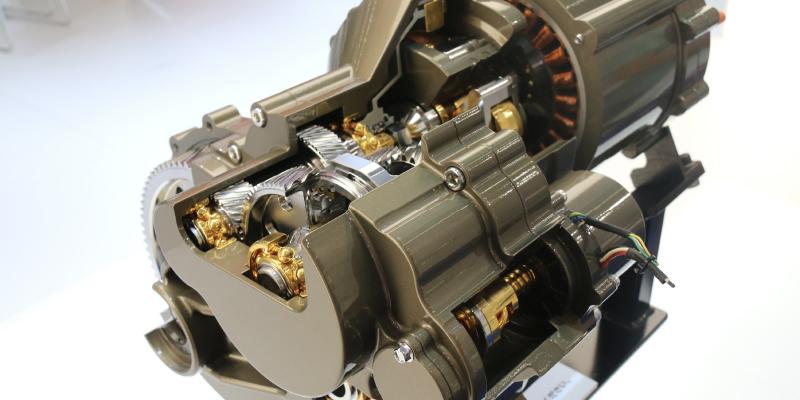

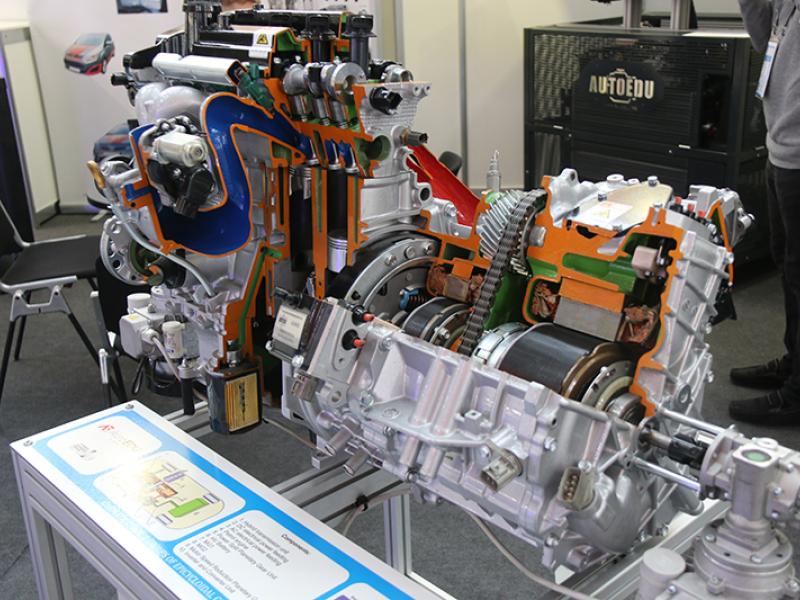

What then, is checked, in addition to the basic stuff like tyres and tyre pressures, brake effectiveness and so on? After all, an EV has no oil to worry about and what’s under the hood is mostly unserviceable parts anyway.

Typically, according to Gavin, customers are most concerned about the health of the battery pack.

They know this is the most expensive single part of an EV, so they want reassurance by way of test and report, that the battery is going to keep doing what it should be doing. Thus, the battery and EV systems take up the lion’s share of the service time.

Following on from this is condition and quantity of brake fluid as this forms a critical element of the EV’s regenerative system and the other thing is coolant levels specifically coolant levels for the battery. After that, it is pollen filters (likely to grow in importance), brake pads (though these should last a little longer) and tyre wear/pressure and wheel alignment.

What then, about specific tools and equipment for the EV-friendly workshop? What’s the advice here? According to Gavin, its best practice to have EV tools separate and in addition to the everyday use ones.

“You are looking at heavily insulated general tools,” says Gavin, “Hyundai workshops for example, source tools and equipment by OEM and industry supplier TransNet NZ, which has an extensive range of individual tools or complete kits for workshops.”

Making the decision to become an EV service and repair workshop was always going to be a challenge for many independent workshops, not only in terms of financial commitment, but also in terms of knowing what was needed to go ahead and do it.

In some respects, workshops have been given a little breathing space thanks to the global changes which have taken such a toll across all industries.

Now is the time then, to seriously look at the options and plan or the future, not just the present.

The good news is, it will be some time before EVs take over from ICE vehicles, so there is room to plan. Just don’t leave the decisions too long.