In last month’s article we took you through automotive brake test engineering from an equipment and automotive perspective

Test results with the same vehicle

Dollowing are some practical tests we have done with our 2018 Hyundai service van (33,000km) on a newly installed plate brake tester and compared the results with a newly installed roller brake tester.

First we had to establish the actual vehicle weight with no driver in the vehicle, no freight and half a tank of fuel.

LHF 698kg RHF 692kg (axle weight 1390)

LHR 528kg RHR 510kg (axle weight 1038)

These weights were verified with newly calibrated traffic police weight scales.

True Total Weight = 2428kg

Practical tests

Following is a series of results of which we can produce photos and video.

Realise that the tests have been done with the same vehicle within minutes from each other.

Since the weight was not calibrated correctly on the tester, we used the confirmed static (empty) weight of the vehicle for the actual efficiency calculations. If you add the driver to the weight used the ‘actual efficiency’ lowers by about 4 percent on an axle weight of +/-1000kg, making the discrepancy between actual and displayed efficiency worse.

Test 1: Plate brake results Normal drive on, with gradual braking

|

|

Axle brake force measured |

Actual axle weight empty |

Displayed axle weight |

Actual |

Displayed |

|

Front Axle |

5,507N |

13,622N |

10,966N |

40.4% |

50.2% |

|

Rear Axle |

539N |

10,172N |

7,859N |

5.2% |

6.8% |

|

Total Vehicle |

6,046N |

23,794N |

18825N |

25.4% |

32% |

The tester shows a total vehicle efficiency of 32 percent, calculated with the actual axle weight this is 25.4 percent, that is in all rule books a WoF fail on this late model vehicle!

Test 2: Plate brake results Normal drive on, harder braking

|

|

Axle brake force measured |

Actual axle weight empty |

Displayed axle weight |

Actual |

Displayed |

|

Front Axle |

7,070N |

13,622N |

10,887N |

51.9% |

64.9% |

|

Rear Axle |

3,421N |

10,172N |

7,849N |

33.6% |

43.6% |

|

Total Vehicle |

10,491N |

23,794N |

18736N |

44% |

55.9% |

The tester shows a total vehicle efficiency of 56 percent (a WoF pass), calculated with the actual axle weight the efficiency is 44 percent, that is still a WoF fail.

Test 3: Plate brake results Faster drive on, with gradual braking

|

|

Axle brake force measured |

Actual axle weight empty |

Displayed axle weight |

Actual |

Displayed |

|

Front Axle |

7,316N |

13,622N |

10,976N |

53.7% |

66.6% |

|

Rear Axle |

2,430N |

10,172N |

7,898N |

23.9% |

30.7% |

|

Total Vehicle |

9,746N |

23,794N |

18874N |

41% |

51.6% |

The tester shows a total vehicle efficiency of 52 percent (a WoF pass), calculated with the actual axle weight the efficiency is 41 percent, that is still a WoF fail.

Test 4: Plate brake results Faster drive on, harder braking.

|

|

Axle brake force measured |

Actual axle weight empty |

Displayed axle weight |

Actual efficiency |

Displayed efficiency |

|

Front Axle |

12,158N |

13,622N |

10,848N |

89.2% |

112% |

|

Rear Axle |

6,815N |

10,172N |

7,869N |

67% |

86.6% |

|

Total Vehicle |

18,973N |

23,794N |

18,717N |

79.7% |

101.3% |

The tester shows a total vehicle efficiency of 99 percent. This is not possible (!) and it is rounded down from 101.3 percent, calculated with the actual axle weight the efficiency is 79.7 percent.

Please realise that all brake tests are done with the same vehicle with the same trained operator within minutes of each other without locking up the brakes.

Looking at the reasons for some of these results, the brake plate tester in reality can only provide reasonable consistent results when a car with locked up brakes, is pulled across the brake test plates in a gentle manner (wheel skid).

The rope used for pulling the vehicle across the plates needs to be perfectly horizontal to make sure no weight is added or is removed from any axle. This test still does not test the full circumference of the brake.

Brake plates are still around because they are incredibly cheap to produce compared to brake rollers so provide a lower price point. The actual brake force sensor is really the only ‘expensive’ part that both types of testers share.

In a plate brake tester there is a lot less steel, there no chains, motors, gear boxes, speed sensors, or rollers. They are also very cheap to install if they are (incorrectly) fitted above ground.

Plate brake testers can produce variable results on the very same vehicle back to back by slightly varying how the test is performed as our research above shows.

A plate brake tester should use dynamic weight during a brake test in which you will have to lock the wheels to calculate properly axle efficiency.

The difficulties are:

• The shift in weight (inertia of the vehicle) when braking increases the brake force on the front axle and decreases the maximum brake force on the rear when lock-up occurs.

• Some of the brake force will be transformed into weight reading due to the momentum on the brake plate.

• When driving onto the brake plates when they are above ground (not flush), causes weight oscillations.

• Lock up on the plates gives weight oscillations and brake force oscillations.

On brake plates the brake force oscillations and weight oscillations need to be matched carefully and rebound must be removed from the results before efficiency can be reasonably calculated.

It is for this reason that back in the nineties the engineer’s setup the software to use static weight in efficiency calculations. What we have found during our research about 23 years later that on equipment available in NZ static weight is still being used!

That is immediately visible by anyone using a plate brake tester when brake efficiencies are unrealistically high without even locking up the wheels.

We have seen testers producing results of more than 100 percent brake efficiency without any ‘aerodynamic downforce’ in the workshops!

On the plate brake tester to get accurate test results and comparison between the front and rear axle you need to test both axles at the same time, at the same spot of the plates. To do this for example on the front axle first and the rear axle later, produces meaningless results as the speed and deceleration rate of the vehicle will be different (subjective results).

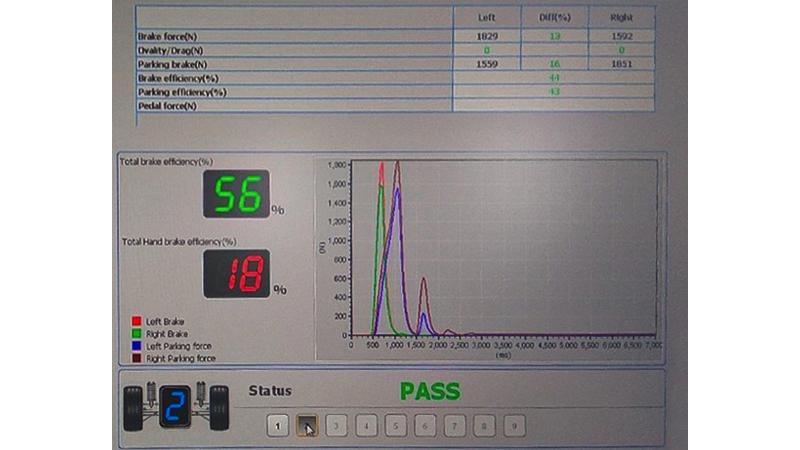

Roller test results

Below are the brake test results of the exact same vehicle on a recently installed STT45 truck roller brake tester (in truck mode). The weights are with a driver and some tools in the vehicle

Please note on truck brakes the difference should be not greater than

30 percent (<=30) over 4KN.

If we break down the results, we get the following:

|

|

Axle brake force measured |

Actual axle weight empty |

Dynamic axle weight |

Actual efficiency |

Displayed efficiency |

|

Front Axl |

8,940N |

13,622N |

14,984N |

59.7% |

60% |

|

Rear Axl |

6,420N |

10,172N |

10,045N |

63.9% |

64% |

|

Total Vehicle |

15,360N |

23,794N |

25,029N |

61.4% |

61% |

Testing of this vehicle can be repeated over and over by any operator with always similar results, with very few exceptions (e.g.slamming brakes).

To prove the consistency of a modern roller brake tester we have tested the same front axle four times in one test. Below are test results of very different brake applications, from gentle braking to slamming the brakes.

Please note the time base and the lock-up brake force in each graph.

Screen dump of four times the same front brakes of the same vehicle.

In the above graph you can see that only when you slam the brakes on a slight increase of lock up brake force is measured as a result of the brake rollers and motor inertia.

There are many more tests and conclusions that were made, which are not covered in this article, to keep the length of this technical article under control. Like, for example, grip coefficient of the plate surface and workshop floor, brake balance, difference, drag, ovality, centre of weight shift, and much more.

Conclusion

Are cheap brake testers really worth it? Please note that plate brake testers are actually not approved for CoF B in NZ but are currently for WoF. Should we as an industry look at ourselves and use the best practice for the good of our credibility, rather than wait for the law to regulate and forbid certain types of testers for WoF? AECS will not distribute testers we do not believe in, we keep it simple and clean, helps us sleep well at night!