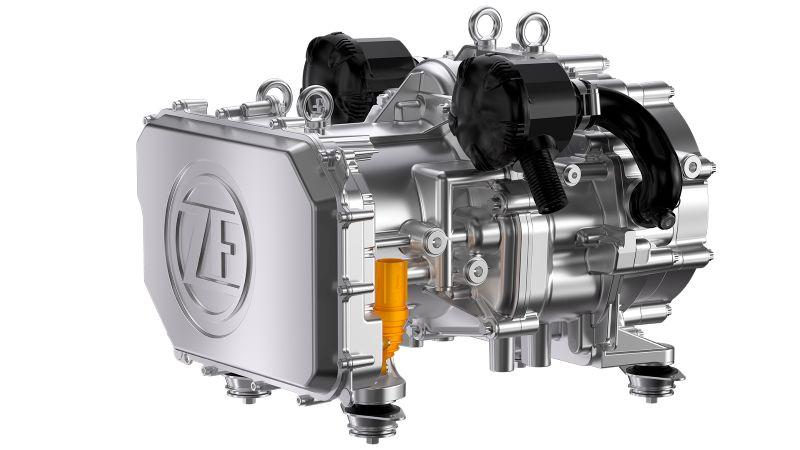

ZF’s Commercial Vehicle Solutions (CVS) division unveils its latest electrification technology, a new and advanced air compressor for commercial vehicles. Designed as much for efficiency as it is for smooth operation, the e-comp Scroll is an oil-free, low-noise and minimal vibration air compression system for medium and heavy-duty hybrid, battery electric and fuel cell trucks, buses and coaches. The new product has its public premiere at the Advanced Clean Transportation (ACT) Expo in California, USA, and at the Auto Shanghai in China.

Compressed air continues to be a fundamental requirement in commercial vehicles as the industry transitions towards electrification, supporting core and safety critical systems such as air disc brakes and suspension as well as other auxiliary functions. In commercial vehicles with electric drives, the air compressor required for these functions is usually driven by its own electric motor, unlike conventional vehicles in which the compressor is powered by the combustion engine.

With electric vehicles operating more quietly than traditional ICE powered vehicles, the noise generated by the conventional piston compressor becomes more noticeable, negatively impacting the comfort of those inside and outside the vehicle. The e-comp Scroll solves this by using the motion of interlocking scrolls to compress air. This minimizes vibration while limiting noise emissions to around 67dB(A) at the nominal operation point of 250 litres per minute, comparable to the noise level in an office environment.

“By offering an oil-free, low-noise and low-vibration air compression system, we are addressing the technological challenges posed by zero-emission targets for electric vehicles,” said Head of Product Line, Chassis Solutions, for ZF CVS, Paweł Porczyński. “The innovative design of the e-comp Scroll ensures efficient air compression while significantly reducing Total Cost of Ownership (TCO) through low maintenance resulting from elimination of oil lubrication. By automatically switching off between compression cycles, the e-comp Scroll saves energy while enhancing the overall experience for the driver, passengers and other road users alike.

“It also expands our growing portfolio of innovative products and systems that help drive the industry’s transformation towards zero-emission commercial vehicle mobility.”

Powered by an integrated electric motor, the e-comp Scroll efficiently compresses air up to 12.5 bar system pressure in a single stage and is capable of running at variable speeds to meet application demand. The technology fulfils diverse customer requirements, such as system pressure, free air delivery, size and noise levels. Operating oil-free, the e-comp Scroll eliminates oil leaks as well as oil disposal needs, reducing TCO and protecting the environment.

The system also features an inverter and liquid cooling shell, which maintains the discharge temperature below 90°C (194°F).