Clutch replacement on vehicles that are out of factory warranty has certain pitfalls, and one of the biggest challenges automotive technicians face is correctly identifying the thickness of the clutch brake to install.

To help unravel some of the mystery surrounding the correct installation of clutch brakes, Exedy product manager, Mark Davis has taken the time to share his tips.

“When installing a new clutch on a commercial vehicle that has seen plenty of road duty it’s critical to identify the correct thickness of clutch brake prior to installation,” said Mark. “No matter what you’ve heard, flywheels need to be ground with every new clutch installation.”

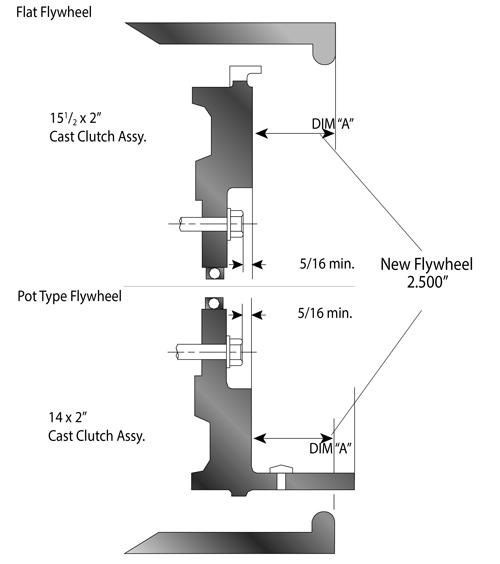

To add a little more complexity to the task, sometimes the front bearing cap on the transmission is not replaced and instead reground; as such it is imperative to determine the size of the “clutch envelope” (distance between the flywheel and the front bearing cap).

“When the truck is new, this measurement is 8.094 inch (205.59 mm),” Mark explained. “To determine this measurement on your truck, lay a rigid flat bar across the flywheel housing and measure, using a micrometer, the distance from this bar to the flywheel (you must subtract the thickness of the bar if measuring to its top) and anything over 2.500 inch (63.5 mm) will reveal how much has been ground off the flywheel from its “new” thickness.”

The next task is to make sure the front bearing cap on the transmission is replaced.

“A standard clutch brake is 3/8’ thick (9.53 mm),” Mark said. “So when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to identify the clutch brake which is nearest to the required thickness.”

Eexedyt clutch brakes, depending on the style, are available in the following thicknesses: 0.375 inch (9.53 mm); 0.400 inch (10.16 mm); 0.450 inch (11.43 mm) and 0.500 inch (12.7 mm).

In addition to the thickness shown above, 1/8 inch (3.18 mm) fibre washers are also available to facilitate minimum adjustment in the new clutch.

By installing a clutch brake nearest to the size required you will not need to turn the adjusting ring on the clutch, when new, any more than one or two notches, which will help extend the life of the new clutch.

“Turning the adjusting ring will, at minimum, diminish the life of the clutch, and could in fact cause an internal failure in the clutch when it is new,” he said. “The objective when installing a new clutch is to MINIMISE the adjustment necessary to attain the half inch gap (12.7 mm) between the top of the bearing and the clutch brake.”

This will ensure the clutch achieves maximum life and reduces the chance of internal failure when the clutch is new.

For additional installation tips and to discover more about EXEDY’s TUFF TRUCK range of quality commercial vehicle clutches visit exedy.co.nz.

The Truck Tuff range includes replacement clutch kits for light, medium and heavy commercial vehicle’s to suit Japanese, American and European applications. The Truck Tuff range is specifically designed to suit New Zealand conditions.