It doesn’t matter if your customer is an owner-driver or a large logistics company, vehicle downtime due to product failure can be costly. That’s why it’s important to specify quality components. Beware of cheap imitations, as a low price can be indicative of shortcuts in material quality and workmanship, which can lead to expensive repairs down the road.

Case Study – Competitor Clutch

Disc Torsional Durability Test

Have you ever experienced a successful clutch installation only to have the vehicle being towed back into your workshop a few months later? The cause of clutch failure can often be traced back to the material composition, lack of engineering know-how and poor-quality workmanship.

To illustrate the difference between Exedy and competitor products being sold in our market, periodically we test our competitors’ products to see how they stack up. For example, in the case below, we have conducted a clutch disc damper torsional durability test, which revealed that the competitor’s disc damper failed after 1.9 million cycles. Given that the standard for an Exedy disc is 3 million cycles with no evident failure of the damper components, it is clear that the competitor’s product does not offer the same level of quality and if installed into a vehicle, would have contributed to a premature clutch failure.

Exedy Disc Ref HND058U – Application Hino GH Series.

Broken torsional spring after 1.93 million cycles.

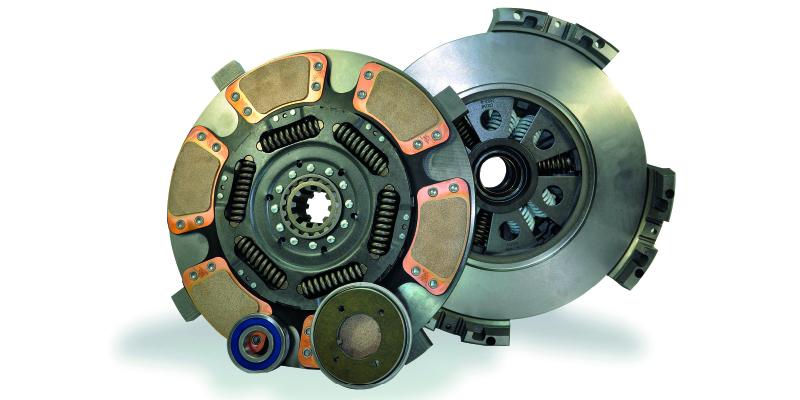

As the leading manufacturer of Japanese commercial clutches, we often find that competitors attempt to replicate the Exedy product style. This can be problematic, as our customers who are familiar with the appearance of an Exedy clutch may be deceived into purchasing an imitation part. The image below is an example of a competitor’s disc, which was designed in such a way that the coupling plate, ceramic button, retaining plate and spring configuration resembled an Exedy product – even down to the laser etching of the Exedy part number ISD081B6!

Case Study – Competitor Clutch Cover Assembly

In a similar fashion to the clutch disc, whilst the clutch cover assembly may look like the genuine Exedy part, our team had identified a number of important differences.

Clutch cover balance:

Upon final assembly of the clutch cover, it is important to subject the finished good to a balancing process; mainly to ensure that the clutch does not cause a vibration once installed into the vehicle. In the case of our competitor’s products, the size and position of the balance weights were poorly selected. This can lead to issues with the balance weights making contact with the bellhousing or other components within the clutch environment such as the release fork. It is also important to balance the pressure plate casting prior to assembly; however, it was noted that in a number of cases, the pressure plate casting had not been balanced.

Pressure plate lever height:

To avoid clutch drag and pedal pulsation, it is important to ensure that the release levers are in parallel when bolted to the flywheel; however, in the case of the competitor’s products, excessive variation in the release lever height was recorded. Furthermore, the release levers had not been satisfactorily hardened on the release bearing contact surface. As a result, there was a variation in the quantity and size of the release lever needle rollers, which can lead to the premature wear of the lever and pin.

Diaphragm spring:

To ensure the longevity of the diaphragm spring, the release bearing contact area should be hardened; yet, upon investigation, it appeared that the sample clutch covers had either not been subjected to a hardening process or the process was insufficient to provide adequate strengthening to

the area.

Failures due to poor quality can result not only in costly repairs, but also loss of income due to time spent off the road.

It’s what‘s in the box that counts and with Exedy, you can be assured that the product you buy has been specifically designed and engineered and tested to suit your vehicle and that it has been manufactured using the highest quality materials. As a long time supplier of OEM clutch parts to numerous commercial vehicle manufacturers, the quality of the Exedy product speaks for itself and delivers exceptional clutch cover diaphragm and clutch disc damper durability for longer clutch life and improved driver safety.

Leading clutch manufacturer Exedy stands behind the quality of its products, especially their reliability and durability in service. Their comprehensive range of Truck Tuff clutches cater for Japanese, American and European commercial vehicle clutch needs. Exedy is New Zealand’s premier Japanese truck clutch supplier, providing the market with a wide range of kits to suit all commercial applications. In addition, Exedy is the largest supplier of clutches fitted as Original Equipment in Japan, supplying the majority of truck clutches to the OEM.

“We have built our reputation on manufacturing a quality product and providing expert after sales service,” said Exedy Product Manager Mark Davis. “It doesn’t matter if you’re working on a light, medium to heavy rigid, or a B-double, we’ve got the right clutch for the job.”

As the primary OEM clutch manufacturer for Isuzu, Hino, Mitsubishi Fuso and Nissan UD, Exedy supplies clutch products for over 80 percent of the domestic Japanese commercial vehicle market. For this reason, Exedy is the first choice when it comes to quality Japanese commercial clutch product.

To help reduce downtime and avoid come-backs, trust the experts at Exedy to help you identify and fit the right clutch for your vehicle. For further information on Exedy’s clutch range, jump online and check out the Exedy Parts Finder: