To maintain the optimal heat dissipation in modern engines requires comprehensive maintenance focusing on the overall health of the cooling system, the components integrity, and corrosion control.

Modern cars have smaller engines that operate at higher temperatures, higher speeds and often with turbocharging. Car design also puts a premium on minimising mass and size of cooling system components for maximum aerodynamic and fuel efficiency. All of this means that modern cooling systems run much closer to the edge and any drop off in performance due to poor maintenance can become critical more quickly.

Some key maintenance practices to ensure the system continues to operate efficiently:

System and component inspection

• Routine Inspection: Inspect the complete system when servicing vehicles, especially leading into warmer summer months looking at the overall system and the individual components. Make sure you also check for any foreign matter blocking air flow to the radiator such as mud/leaves and debris.

• Post-Repair Checks: Following a major engine repair or rebuild, it is essential that the vehicle’s cooling system is thoroughly checked.

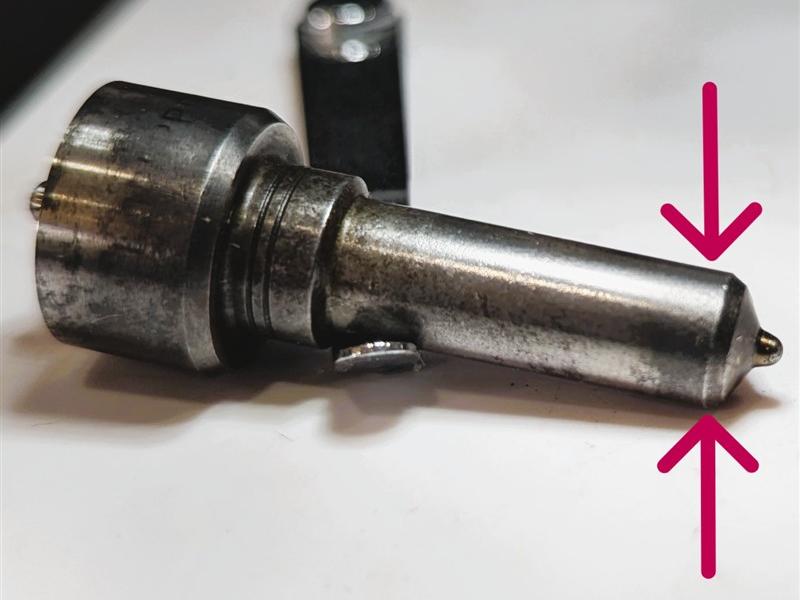

• Component Maintenance: All components, including the cooling system hoses, radiator, water pump, thermostat, thermal switch, fan, radiator cap, and expansion tank cap, must be maintained in good condition and replaced when worn or faulty. A worn pressure cap, corroded water pump, or kinked hoses can significantly decrease the system’s ability to dissipate heat, potentially leading to overheating and subsequent engine damage.

Coolant

The efficiency of heat absorption and transfer is severely reduced by corrosion or contamination, the choice of and regular replacement of coolant, using the recommended type for the engine, is the best strategy to avoid this as the protective properties of the corrosion inhibitors become depleted over time, which can allow internal corrosion to start.

Hose integrity

Cooling hoses are essential components of the system, check for any damage to hoses –including internal damage from electrochemical degradation, leakage, heat, ozone, abrasion, or oil contamination, any of these can restrict the flow of coolant and cause the cooling system to fail. Ensure that any replacement hoses are correctly specified, modern engines need hoses designed for the higher heats of modern engine bays.

Other components

Whilst we have focussed on the engine cooling system above the transmission oil cooler, engine oil cooler (if fitted) and any intercooler is also an integral part of the vehicles thermal management system. They should be checked in a similar manner to the rest of the system.