When it’s time for a brake pad change, the old pads are often thrown away without being given much thought, but the way pads wear can help diagnose broader issues within the braking system.

In an ideal situation, no matter what the vehicle or caliper design, brake pads should wear evenly on all axles. Even wear on the old pads confirms that all the braking hardware has operated as it should. But if there are signs of inner, outer, tapered pad wear or glazing and cracks, these are underlying issues.

Outer pad wear

As the name suggests, this is a condition where the outer part wears at a greater rate than the inner pad. It’s a scenario that’s typically caused by the pad maintaining contact with the disc brake rotor after the brake calipers retracts.

Calipers are made up of many components including a piston(s), seals, dust boots, locking bolts, slide pins and mounting brackets – several of these are moving parts which can make them susceptible to seizing or failure. If this is the case, caliper inspection is recommended.

Inner pad wear

Inner pad wear is more common than outer wear, particularly on a floating caliper brake system. The difference in wear rate (between the inner and outer pad) should be quite marginal, perhaps only a couple of millimeters.

Anything more and again, it may be time to take a closer look at the brake calipers, which may not be retracting smoothly; this could be caused by a seized guide pin or slides. Given the location of the caliper close to the road and being hit by water, road grime and other muck, calipers can be prone to corrosion and seals and dust covers can become brittle and cracked, allowing contamination.

Another potential cause of outer pad wear could be an issue with the brake master cylinder, which is causing the caliper to stay engaged with the rotor longer than it should.

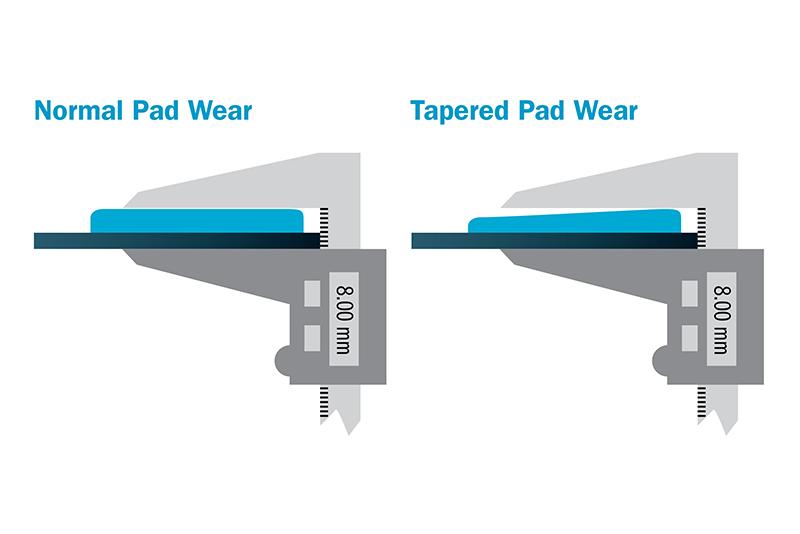

Tapered pad wear

Tapered pad wear occurs when the friction material is worn in a horizontal or vertical wedge pattern, it means that one section of the brake pad is making greater contact (or force) with the disc rotor when the brakes are actuated.

Rate of wear will depend on how many piston calipers the vehicle has. In a single piston caliper vehicle, when the brakes are applied, the leading edge of the brake pad is more likely to dig into the rotor, causing it to wear at a greater rate. Multi piston calipers and calipers with staggered pistons (pistons of different size), are less prone to tapered wear.

Other causes of tapered wear could include improper pad installation, corroded abutment clips or worn guide pins and bushings.

Cracked, glazed or lifted edges on the friction material

These conditions normally arise when the brake pads have operated at excessive temperatures and beyond the friction material tolerances. This can be caused both by bad driving habits and by brake system issues.

Hard driving including repeated heavy braking and braking on long descents – particularly when heavily loaded or towing – can quickly elevate brake pad temperatures, causing the friction material to break down. Riding the brakes will have the same effect, as will having calipers that don’t retract properly. As well as increasing wear rates, these situations can also result in ‘brake fade’, reducing the effectiveness of the braking system and decreasing vehicle safety.