I’m sure many of you didn’t think you would work on so many diesels as often as you do today. Especially those who didn’t sign up for it. One of my growing concerns is so many of you blindly diving into the older diesel vehicles. They are different to common rail systems, just like common rail diesel (CRD) itself is different from EFI petrol as some have found out the hard way. Sure, they both have wires and an ECU but remember how difficult it was for some of you to get your head around the intake, exhaust and the fuel hydraulic principles of the CRD. Well the earlier design rotary diesel pumps are different again. Most of your customers with the older diesel’s are going to expect you to know this. In their minds, it has got wheels and the engine drives them. You leap frogged this old diesel gear so be prepared for another learning curve if you decide to venture this pathway. Me, well I was fortunate to experience every phase of diesel injection system from the 90’s to current.

Pic 1 Nissan Patrol

One old diesel system I just cannot be rid of is the Nissan ZD30. An endless headache for us earlier on with little or no network support trying to figure out the engine fitted to Patrol and Navara. Moving onto now, I see the light at the end of the tunnel. It is second nature for me when our Diesel Help members log these and other early diesels. I do enjoy dealing with these for a several reasons:

- The opportunity to teach our members a completely different diesel system.

- Our members gain a better understanding of all diesels.

- I know I have still got it- my memory and my sanity.

Other than the new diesel diagnostics experience, the challenge for you is convincing your customer to spend money fixing it properly. The VP44 pump on some applications can fetch a price higher than the entire car is worth! Remember these important rules- You are not a financial adviser, do not judge someone by the car they drive nor their appearance, and most important be honest.

Don’t tell the customer ‘It’s not worth spending on this vehicle’ just to avoid working on it. It may not be a fuel pump problem. Unless you are in the business of only reading codes and charging a customer to make you feel better, do not take the job on at all. There are still plenty of car owners who are either not in a position to update or would rather reinvest in the car they know.

The ZD30 engine is often fitted to the Nissan Patrol GR /Safari (Y61) ZD30 released in Australia in 2000 and soon after in the D22 Navara up until 2006. There is a distinctive difference from these earlier ZD30 engines and the later CRD models. You can tell without lifting the covers.

Pic 2 eng cover Non CRD ZD30

Pic 3 eng cover CRD ZD30

The vehicle will have approximately 100,000kms or more. Some will have fault codes, most will not give you any information to go on. You may see one of the following codes, dependent of your scan tool communicating with the vehicle.

76 – refer to official manual/injector pump 6 (Spill V)

47 – RPM sensor (TDC Signal Side)

73 – Injection pump 3 (Communication line)

Before jumping to the conclusion, the injection pump has failed, I have provided a list of several possibilities why the engine will not start.

Starter Motor: The injection pump fitted to the ZD30 is referred to as a VP44. Like CRD injectors, the Spill Valve requires high amperage to operate. The Spill Valve located between the four fuel delivery outlets fitted at the rear of the pump, controls how much fuel is delivered to the mechanical injectors located in the cylinder head. When the starter motor is becoming worn, during cranking it may draw too high current, thus leaving the Spill Valve with little chance of delivering enough fuel to open the pressure dependant injectors. Sometimes the starter motor appears to be spinning over like a brand new one, yet a ‘polling’ effect can cause the high current draw, preventing the engine from starting.

Pic 4 Spill valve location

When diagnosing a difficult or no starting diesel, a quick reference to determine is fuel injecting would be to look for a common symptom - smoke. When no smoke is present, try a quick test by connecting a second battery or battery boost pack to assist. If the engine jumps into life, you can now confirm poor current supply is the issue. Often a common hard to no start fault with smoke might be an engine with low compression. White smoke would be evident in this situation. White smoke is common to occur on earlier non CRD rotary design pumps when either air is entering the fuel pump, or the advance timing unit has failed. Air in the diesel can also contribute to the retarded timing situation.

Air in the fuel: When there is too much air entering the fuel supply, then you may experience a case of no smoke during cranking. This can be confirmed by connecting clear hose or even better, run the Eliminator directly to the pump. When connecting the separate fuel supply (Diesel Helps Eliminator), always plumb it directly to the pump and ensure you have bled all the air from the system. One minor mistake made on these systems, is trying to bleed the air using the hand pump. Even the Eliminator hand pump will not overcome the 3-bar pressure relief on the return banjo bolt situated on the injection pump. I recommend removing this bolt first to assist with bleeding the system and to reduce the possibility of fuel pump failure.

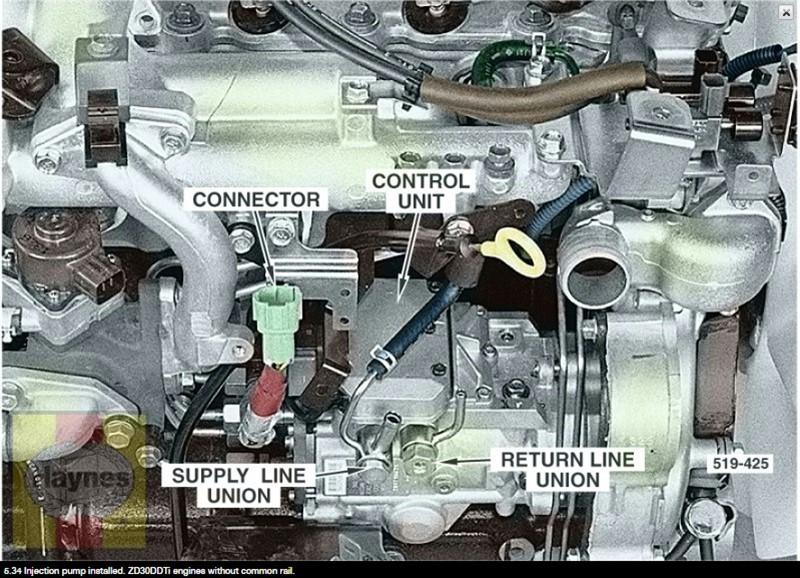

Pic 5 VP44 injection pump return

Once you have confirmed fuel supply to the pump and cranking the engine the voltage remains constant above 10.3 volts, during rotation you should witness fuel drawn through the clear hoses. If no fuel is drawn especially when running the separate fuel supply, there are only a couple of possible failures remaining. Either the internal transfer pump has completely failed or there is no communication with the built-in injection pump control unit. Several factors contribute to this. The pump relay has failed, poor earth, Crank angle sensor failure or the injection pump control unit and or wiring has failed.

On the pump itself there is a short harness connecting to the main security lock harness. Test the continuity and inspect on the pump itself for a common aging fault- wiring coating becoming brittle to the spill valve. There are so many other faults we see on the ZD30 as well as other older diesel models. Please keep a look out for our ‘Old Diesel training courses or alternatively you can join Diesel Help. Our members reckon its worth every cent and often gain a learning experience, not just a quick fix of the diesel.

*Specifications obtained under license agreement with HaynesPro Workshop Data and Haynes AllAccess. Haynes Australia Pty Ltd grants Diesel Help Australia permission to republish this material.