By John Oxley

It’s almost as if there’s a race to save the internal combustion engine, with more and more brilliant ideas focused on making petrol and diesel engines more efficient, more frugal, and cleaner.

The latest idea – and one we’re surprised hasn’t been thought of before – is to replace the good old-fashioned flywheel with a lightweight rotor fitted with electromagnets.

It’s all down to the inherent imbalance of a four-stroke internal combustion engine; with only one energy power stroke per revolution (on a four-cylinder motor) the other strokes, exhaust, inlet and compression, produce counter-energy, eliminating some of the power produced by the power stroke, and also cause lots of vibration.

Early in the development of the ICE, of course, it was discovered that putting a large flywheel on the end of the crank would even out the pulses, but this brings its own disadvantages.

The larger the flywheel, the smoother the engine. But a large flywheel takes a lot of power to get it going, meaning engine pickup is slow. Lighten the flywheel, and the engine leaps into life, but this comes at the expense of torque.

Those of you who have built racing engines will know that a lighter flywheel allows the engine to pick up very quickly, but it’s at the expense of low-down power, making the engine “peaky”. Dual mass flywheels go a long way to helping, but at the end of the day, after more than 100 years of development, they are still a compromise.

Until now. American inventor Randy Moore has patented an idea for an electromagnetic rotor which replaces the flywheel..

He explains: “On a four-stroke engine, each piston has to go through two complete cycles before it can get another burst of energy (power stroke). In order for this piston to reach the next power stroke it must overcome many factors such as piston ring friction, cam operation, etc., and then it must go through a final compression stroke before reaching the next power stroke.

“Obviously the engine must supply more fuel to overcome these factors. Designers add flywheels to engines to maintain the extra inertia needed for the engine to reach its next power stroke, but the

flywheel weight can reduce the acceleration because of its extra inertia.”

Randy’s patent provides a burst of energy at the moment when piston friction subsides. The component—a lightweight magnetic plate—has the potential to add extra torque to the engine while reducing inertia.

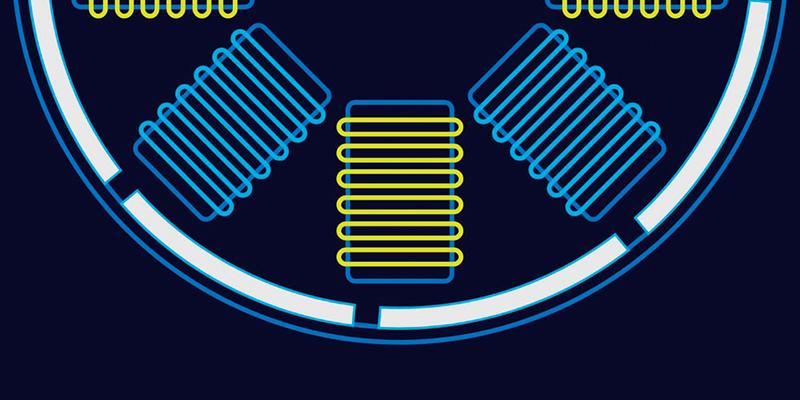

In the place of a flywheel, the RK Transportation solution is to add permanent magnets to the rotor assembly, enabling bursts of perfectly-timed energy to the engine by attracting and repelling the magnets from stationary coils.

“This innovation stands to have a huge impact on small engine performance by using electromechanical energy to manage torque output,” says Randy. “With further development, we could replace the flywheel and transmissions currently used, which would allow us to increase power and reduce fuel consumption simultaneously.”

The new technology has been through years of experimentation and is ready to be implemented in real-world applications, for racing research, automotive engines and smaller engines. More info www.rk-transportation.com.