More than three billion ZF brake components have been produced over the past 50 years, Even in the age of software-defined, fully networked and electrified vehicles, a car cannot operate safely without powerful and fail-safe brakes. ZF provides the technological basis for this with its Brake-by-Wire solutions (BbW). The system enables a more flexible vehicle interior and engine compartment design. Depending on customer requirements, braking solutions from ZF can be designed as either purely electric, purely hydraulic or a combined system – providing maximum flexibility.

If you want to arrive safely at your destination, you not only must accelerate, but also decelerate and stop at the right moment. Ideally, the vehicle should also brake on its own if necessary – for example, when a digital emergency brake system brings a vehicle to a standstill independently if the driver is not paying attention. However, today’s braking systems no longer consist solely of hoses, pumps and mechanics, but must also be software-controlled and electrically operated. “Particularly in view of the advances in highly automated driving assistance features, electrified drives and chassis networking, there is no way around Brake-by-Wire in the long term,” says Philippe Gasnier, Head of Research and Development at the Division ZF Chassis Solutions.

Brake-by-Wire ‘dry’: Purely electric braking power

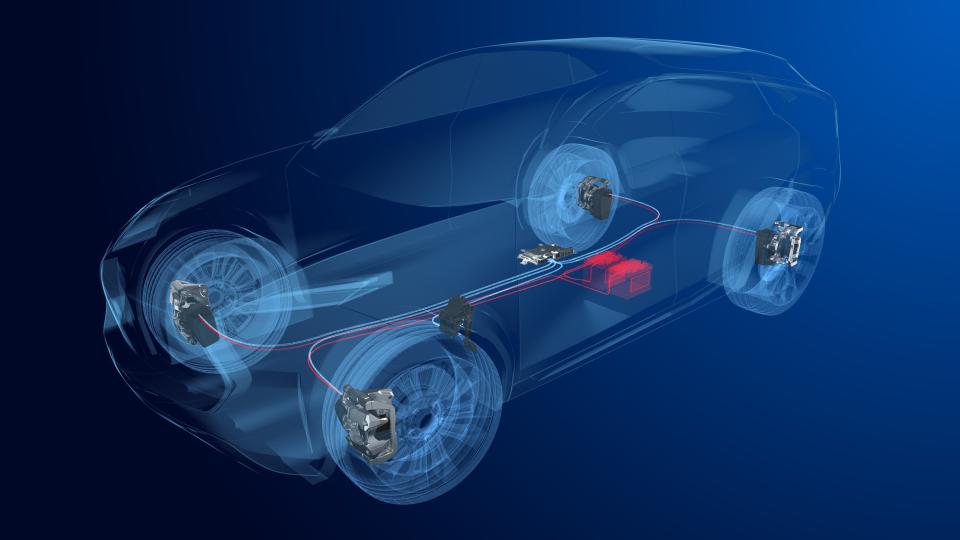

With a so-called ‘dry’ BbW brake system, no brake fluid is required. The pressure with which the brake shoes grip the brake disc is no longer generated by fluids in the hydraulic system, but by electric motors located directly on the wheel. The brake signals from the pedal to the actuator are also transmitted purely electrically. The electro-mechanical brake (EMB) is therefore more responsive and enables optimised recuperation in vehicles with an electric drive, as well as lower maintenance costs. Dry by-Wire solutions have advantages over traditional hydraulic brakes, particularly in highly dynamic manoeuvres such as simultaneous braking and steering. “Modern vehicles are becoming heavier and heavier, so it is all the more important that the ideal brake pressure is built up in the shortest possible time,” summarises Danny Milot, Head of Engineering Product Line Braking.

In addition, BbW reduces the so-called residual drag torque, which occurs in conventional brake systems due to minimal contact between the brake pads and the brake discs, to almost zero (“true zero drag”). This results in even fewer particulate emissions due to abrasion of the brake pads.

For manufacturers, BbW systems reduce costs and effort. Because fewer parts are required, logistics are streamlined and assembly is also simpler and faster. “Demand for such dry systems has risen sharply in recent years, particularly in the Asian market,” says Gasnier. “This shows that we are on the right track with our innovations.”

Brake-by-Wire ‘hybrid’:

The best of both worlds

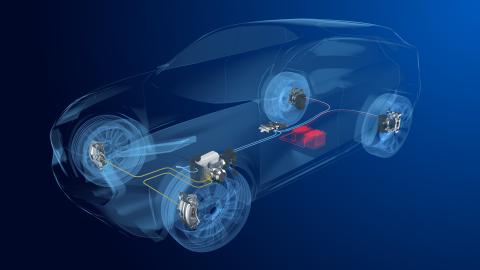

While the Asian market is increasingly relying on dry by-Wire brakes, so-called ‘hybrid’ solutions are becoming established in the USA. The rear axle is usually equipped with a dry system, while a conventional hydraulic brake is used on the front axle.

This application is particularly suitable for the heavy-duty light and pick-up trucks that are widely used on the American market. For this type of vehicle, the high clamping forces required to park the vehicle on the rear axle cannot be handled by an electric parking brake (EPB) but can be handled by the electromechanical brake from the ZF portfolio. In a hybrid system, the EMB is used both as a service brake and as a parking brake. The combination of a fully integrated electro-hydraulic brake control system and an EMB eliminates the need to use a vacuum brake booster. This makes the application less complex compared to purely hydraulic systems and allows more flexibility in the development of the chassis without sacrificing the safety and performance benefits of Brake-by-Wire. In January 2025, ZF announced its first major order from a global OEM for such a hybrid system.

Integrated Brake Control: Highly integrated brake control for all vehicle types

ZF’s Integrated Brake Control (IBC) is responsible for controlling the brake system for this major order. Compact, lightweight and flexibly suitable for all vehicle types and drive types from electric city runabouts to full-blown performance crossovers, it offers first-class performance in terms of responsiveness and deceleration. It functions as a stability control (ESC), brake booster and, if required, a central electronic control unit (ECU) for all relevant driving safety and driving dynamics programs.

“The combination of IBC and our Brake-by-Wire systems guarantees our customers a future-proof solution for controlling braking and driving dynamics,” summarizes Gasnier. “And together with our Brake-by-Wire systems, we can offer our customers a solution that is comparatively easy to integrate, even with innovative platform architectures and increasing requirements.”