REDARC has fielded many inquiries from customers over the years relating to the problems they experience with the charging of dual or auxiliary batteries in late model vehicles.

Simply, the vehicle alternator was never designed to fully (100 percent) charge the main vehicle battery. It was designed to maintain the charge of the main vehicle battery and run the electrical loads (i.e. lights and fans etc.) once the vehicle is running.

Introducing extra batteries into the vehicle charging system with the expectation that the alternator will recharge them fully, from a partially or fully discharged state, is not realistic. These problems have been exacerbated with the introduction of ECU controlled and temperature compensating alternators. These alternators can be found in many late model vehicles such as the Toyota Prado, Hilux and Land Cruiser with the D4D. They reduce the alternator output voltage to approximately 13.2 volts when the engine reaches operating temperature.

Other vehicles such as the Nissan Navara and Pathfinder, Ford Ranger PX1,2&3, Volkswagen Amarok V6 and many, many more use ECU control to reduce this charging voltage even further to approximately 12.5V under certain driving conditions. The range of vehicles with these types of charging systems is continually growing as vehicle manufacturers strive to conserve engine power to save fuel and decrease emissions. The charging of dual or auxiliary batteries regardless of where they are located has now become more difficult.

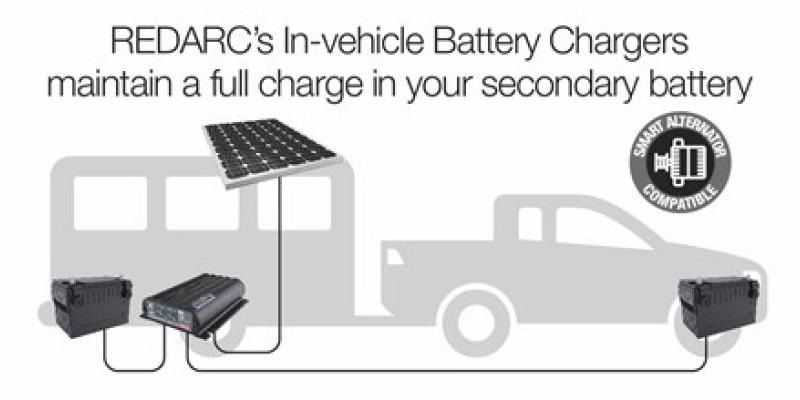

When the auxiliary battery is located a considerable distance from the charging source, for example in the rear of the vehicle, or in a caravan, the resistance for charge to get to your auxiliary battery increases. In turn this decreases the voltage and resultant charge in the auxiliary battery.

REDARC has successfully provided a solution to these problems with the release of the BCDC In-Vehicle Battery Charger range – a Smart Start microprocessor controlled, DC/DC 12 volt charging system. The BCDC is available in three main high current output models, the BCDC1220 with 20 amps of charging power from the DC source, and the BCDC12**D with 25, 40 or 50 amps of charging power from the DC source or 12V solar panels with their inbuilt MPPT Solar regulator.

The BCDC is designed to overcome voltage drop and provide a full charging voltage, from as little as a nine volt DC input. It will recharge and maintain the auxiliary batteries to 100 percent by using one of four charging algorithms (selectable on installation). The BCDC includes special charging programs for Gel/AGM, standard (flooded) lead acid and popular Calcium type batteries as well as LiFePo4 Lithium batteries and will step up the voltages to the required levels for each of the battery types.

Developed by REDARC, the innovative control of current and voltage allows the BCDC to charge a battery correctly even when load is applied to that battery. This current control also ensures that there is no excessive inrush of over current intake to the auxiliary battery when it is heavily discharged as can occur with alternator charging. This high inrush current from the alternator can exceed the amount of current the battery is designed to be charged with and will cause damage to the battery over time with repeated occurrences. Choosing between the 20, 25, 40 or 50Amp output should be selected to suit the amount of charging current the battery is designed for, and the amount of load applied during charging.

With in-built smart battery isolator, it will protect the main battery from over-discharge by auxiliary loads.

The BCDC simply waits for the vehicle to start, sensing the charge from the alternator, and will then commence the charging of the dual/auxiliary battery. The first smart charging process is the ‘Boost’ stage. The BCDC will then seamlessly switch to its second stage ‘Absorption’. Once the battery has reached a fully charged state the BCDC will maintain the auxiliary battery at 100 percent with its third stage ‘Float’.

The BCDC In-Vehicle Battery Charger was fully designed and manufactured in Australia by REDARC to perform the most extreme conditions for long periods of time. The high operating temperature capability and fully sealed construction allows it to be used in engine bay installations and will operate optimally in any weather conditions your vehicle will be subject to.

The BCDC will overcome all the problems associated with the charging of dual or auxiliary battery systems, this includes:

• Alternator charging systems.

• Paralleled dissimilar battery types.

• Voltage drop over long cable runs.

• Over-current battery intake.

• 24-volt DC vehicles charging 12 volt DC batteries.

For more info, visit

www.redarcelectronics.co.nz