Gates is one of six Original Equipment (OE) suppliers in the world which makes automatic belt tensioners for new vehicles. These companies benefit from working directly with the OEs, and have first-hand knowledge of specific accessory belt drive systems (ABDS).

This results in access to fundamental system design information when manufacturing a tensioner for the aftermarket. With more than 3,000 engines in the market today, this knowledge is critical to producing tensioners that fit and function like the OE part.

From the quality of the casting to the design of internal components, every aspect of a tensioner is critical to long service life. Inaccurate specifications will cause shortened life, belt noise and vibration, and can compromise system performance.

Gates tested several value grade tensioners. We found value grade tensioners did not meet OE requirements for alignment, tension and damping. Dynamic testing also revealed premature wear of critical internal components resulting in potential customer returns and driver safety issues.

Tensioner pulleys must operate within the same plane as the belt. Any tilt or offset can cause accelerated belt wear, noise, and in extreme cases, the belt can jump off the drive. Premium tensioners hold tight alignment tolerances using precision assembly and machining practices to ensure reliable service. Value grade parts are reverse engineered, and reveal poor alignment right out of the box.

Belt tension is determined by power requirements of each accessory and drive geometry. Premium tensioners ensure correct belt tension as a result of OE knowledge. Value grade tensioners designed by reverse engineering have no OE knowledge to determine system tension requirements. Samples tested revealed improper tension. High tension will cause premature wear and failure of component bearings. Low tension will result in belt noise, slip and false engine codes.

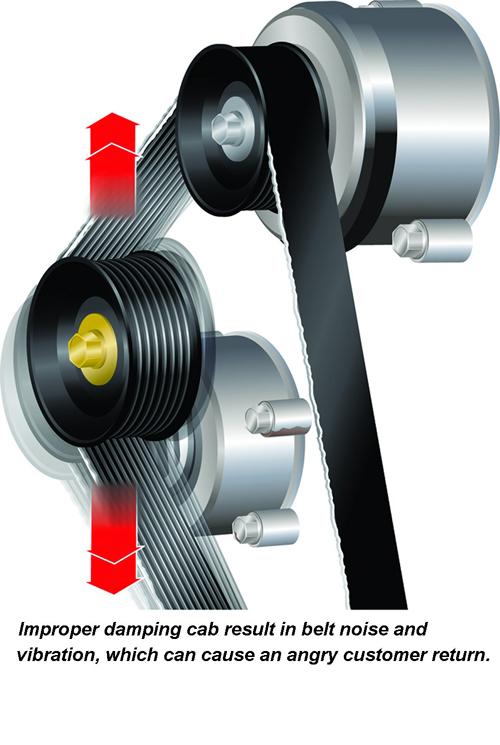

Damping is a critical attribute of any belt tensioner, smoothing peak loads and system vibration. Premium tensioners use patented damping systems developed with the OE knowledge. Value grade tensioners attempt to mimic complex damping systems with no understanding of system requirements. Without proper damping, belt noise, vibration and accelerated wear are likely resulting in customer comebacks.

The body of a tensioner must withstand the forces and vibrations encountered during operation. There is a large difference between premium and value grade casting quality. Premium parts have very consistent grain structures with no discontinuities or porosity.

Value grade parts exhibit inconsistent grain structure resulting in inferior strength. Even the slightest mishandling of a value grade part during installation can lead to failure. Worse yet, because of location, a broken or cracked casting may be hard to detect, leading to potential safety issues.

Gates ensures that every tensioner it manufactures is built to rigid tolerances and specifications that guarantee OE fit, form and function. Premium grade parts eliminate the need to worry about customer comebacks or expensive repairs impacting your bottom line.

For more information about Gates DriveAlign Automatic Belt Tensioners, talk to your Gates Representative or visit: www.GatesAustralia.com.au.