Producing sand moulds with cutting-edge 3D printing technology

This project with mainly young members involved rebuilding the legendary 1951 Toyopet Racer by sticking as closely as possible to the original production methods, seeking to pass on its creators’ car-making philosophy and techniques to the next generation.

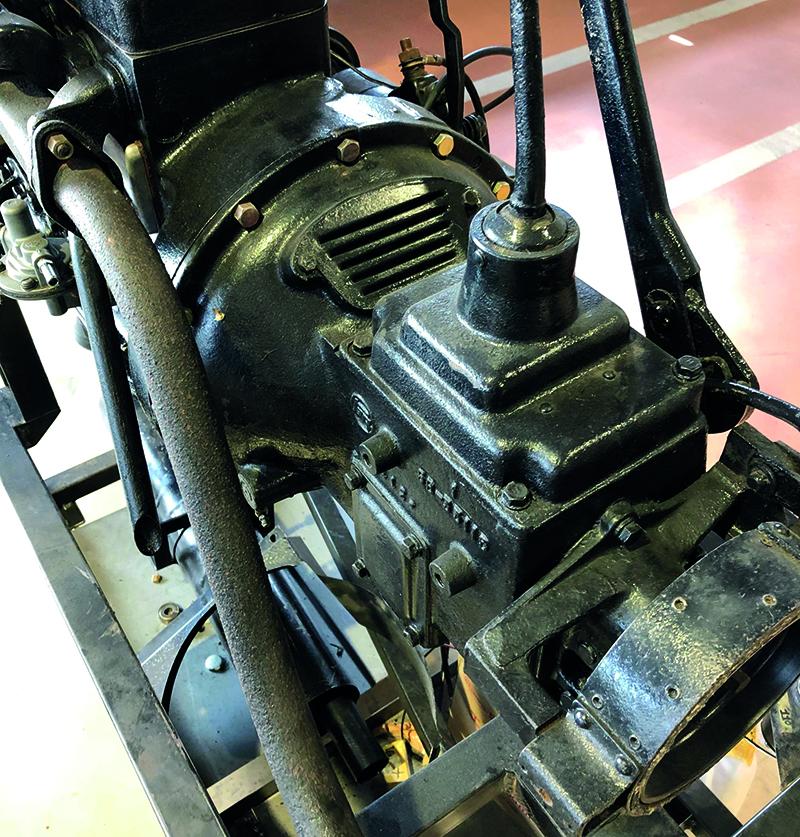

The team responsible for reconstructing the transmission played a crucial role. The challenge of fabricating the cast iron case to house this transmission and other cast parts, such as the clutch and brake pedals, fell to Junya Nakazawa of the Production Engineering Development Centre’s Raw Material Development Div.

Nakazawa comments, “Since I entered the company, I’ve been preparing casting equipment for production and developing production methods.

“I joined this project on my supervisor’s suggestion. As someone working in the development of high-mix, low-volume production technology, I saw this chance to recreate a single car as a great opportunity to further myself and jumped at the opportunity.

“I didn’t know about the Toyopet Racer and was surprised to learn that the car was originally built as part of Kiichiro Toyoda’s vision of developing Japan’s automobile industry.”

The largest part of the racer’s transmission is the cast iron case. In keeping with the spirit of the restoration project, Nakazawa wanted to ensure this part was also created using the original methods.

Doing so entails first making a metal pattern and placing it in sand, which is hardened to create the mould before the pattern is removed. The part is then cast by pouring molten iron into the cavities of the sand mould. However, producing sand moulds in this way is generally expensive and time consuming.

Nakazawa adds, “Ideally, we wanted to create the part using the same mould techniques originally used for the Toyopet Racer. Unfortunately, this method requires repeat prototyping of the sand mould to get the accuracy right, which takes at least a few months. That would not have fit in with our schedule for completing the restoration.

“To get around this, we decided to make the sand mould without a metal pattern, instead relying on the 3D printing used to develop and manufacture engines for racing cars.”

Figuring out the right material

Several steps of preparation were required before the sand moulds could be made using a 3D printer. First, Nakazawa set about deciphering the preserved transmission drawings.

The first step in casting parts is to decide what material to use. Normally, the materials can be identified by the Japanese Industrial Standards (JIS) codes on parts drawings.

It was clear that the original transmission was made of cast iron. However, the ‘CC1’ material code on the drawings did not exist within the JIS standards.

Nakazawa sought the help of Yuji Okada within his department. Okada has been with Toyota for 40 years, having joined in 1981. For 30 of those years, he has worked in casting, developing various technologies, and becoming a specialist in the field. Passionate about cars, Okada has also been involved in developing engines for motorsports.

Okada says, “I had never seen the “CC1” material code, either. We researched the casting materials and technologies used in those days by looking through various resources.

“The design drawings for the Toyopet Model SD on which the racer was based were produced at a time that predates current casting technology and before the JIS standards were established. After reviewing various documents with Nakazawa, we concluded that the ‘CC1’ material is referred to as ‘gray iron’ in JIS classifications.

“The problem is that we don’t use this material anymore at Toyota. Therefore, we opted for FC230 gray cast iron, the closest match among the materials currently in use. With the same production methods, it would look just like the original while ensuring present-day quality standards.”

The difficulties of 3D modelling sand moulds

Thanks to Okada’s help, Nakazawa overcame the first hurdle of finding the right material. With that, he approached the next challenge: turning the preserved hard-copy design drawings into 3D modelling data needed for 3D printing the sand moulds.

In essence, the two-dimensional drawings should contain all the dimensions and other necessary information. However, when Nakazawa began creating the 3D modelling data, he found gaps in the information that made the task impossible. To get around this problem, Nakazawa filled in the missing details by examining the transmission of a Toyopet Model SD kept by a partner company.

Nakazawa comments, “Seeing the actual part allowed me to understand the role of each design feature and whether they were required due to the manufacturing method or for driving performance. I could identify areas where dimensions had to be precise and where they did not.

“Compared to modern transmissions, the design has much padding (areas where the metal is unnecessarily thick). Still, considering the production technologies and methods in those days, I think it’s actually quite efficient in design.”

Unlike cutting processes, where the finished part is formed at a stroke, fabrication by casting involves another hurdle to overcome before a component is complete.

Channels must be designed into the sand mould to ensure that the high-temperature molten iron flows right to the extremities of each cavity to create the desired shape in all its detail and to prevent cavities from forming within the cast parts.

Moreover, because the metal shrinks as it hardens, sand moulds must be made larger than the actual size. Once the cast parts are extracted from the mould, they require finishing work to remove any excess material. These machining margins also need to be added to the size of the finished product when designing the mould.

These issues are solved by creating two sets of 3D modelling data: one for the finished part and one for its preliminary stage.

3D modelling data created from original design drawings

To decipher the 2D drawings, verify the missing information from real parts, and create two sets of 3D modelling data (pre-machining and finished part) for the transmission case, Nakazawa was joined by Raw Material Development Div. colleagues Yuji Fujiwara and Takumi Hasegawa. They had been approached by their supervisor, who spotted an opportunity to nurture young talent in Nakazawa’s mission.

Fujiwara adds, “Normally, I do 3D modelling of moulds for casting engine cylinder heads. This was my first-time producing 3D model data from 2D drawings – and for sand moulds, on top of that.

:We had to figure out what to do with the outdated notation on the drawings, the missing dimensions, and the excess material. All of this was a new experience for me, which was difficult. I was impressed by the level of manufacturing that our predecessors achieved with the technology that was available at the time.”

Hasegawa comments, “My usual work is 3D modelling for suspension components. I knew nothing about the Toyopet Racer and had no experience turning 2D drawings into 3D models, so this was a real challenge.

“It was also my first time being involved in making sand moulds and preparing modelling data for the preliminary stage before completion. Previously, my duties had been more of a supporting role, so being part of the project from start to finish was a first for me and a great experience.”

Meanwhile, the task of preparing 3D models for the clutch and brake pedals fell to Rin Murakami, also from the Raw Material Development Div. Having joined Toyota in 2021, Murakami was still very new to the company when the project began.

Comparing scanner and 3D modelling data to ensure finished part precision

With the 3D modelling data they produced, the team could 3D-print sand moulds for the transmission case and pedals.

The job of manually pouring molten metal into the sand moulds was taken up by veterans from the Production Engineering Development Centre’s Casting Div. After cooling, the parts were removed from the moulds and underwent finishing processes.

Finally, the transmission case and pedals were inspected to ensure that the cast parts had been finished as specified in the 3D modelling data.

Once the iron within is deemed to have hardened, the sand moulds are broken to reveal the cast parts. From here, parts receive the finishing touches, including the removal of excess material.

Expectations exceeded

Despite leading the production efforts, Nakazawa says the finished transmission case, clutch, and brake pedals exceeded his expectations.

Nakazawa says, “The patterns and sand moulds used to cast car parts typically take several years to make, but we were working with limited time. Our solution was to cast the parts in 3D-printed moulds and, thanks in part to the precision of 3D modelling data, they needed surprisingly little finishing.

“Although the process made me painfully aware of how little I knew about casting, I was glad to see that the finished parts exceeded expectations. This task taught me a great deal about how to make high-mix, low-volume production more efficient.

“To be honest, I was initially unsure whether I would be able to complete the parts, but when everyone else came on board to help, I realised that we could get it done. I decided that from now on, I won’t be afraid of new challenges and be proactive in tackling the things I want to do.”

For many members, this project offered valuable experiences not found in their everyday work, starting as it did with creating 3D modelling data from original design drawings.