By John Oxley

Pressure on motor manufacturers to cut down or even eliminate vehicle emissions is growing, and this is having a huge knock-on effect on the battery industry.

As a result the battery world is constantly changing, with new technologies designed to make batteries smaller and lighter, while at the same time holding more charge, and being able to deliver over and over again.

One of the first areas where this affected the industry was the development of stop-start technology, which switches off a vehicle’s engine when it’s stopped, even for a few seconds, thus eliminating wasted fuel and reducing emissions by eliminating the “idling” phase, especially in city traffic jams.

Constantly re-starting a vehicle’s engine, however, puts enormous pressure on its batteries, which have to be able to hold enough charge to get the motor running again, and to keep on holding charge, and this has led to changes in battery technology (see more on P26).

Experts predict that by 2020 stop-start systems will be fitted to 56-million vehicles, with 85 percent of all new vehicles in Europe and 40 percent in the US and China.

It’s probably the single most effective technology available today to limit fuel consumption and emissions, as it’s a relatively easy step for manufacturers to take, with a r high payback of 5 – 8 percent economy gains for a much lower cost than other systems.

And then there’s electric vehicles.

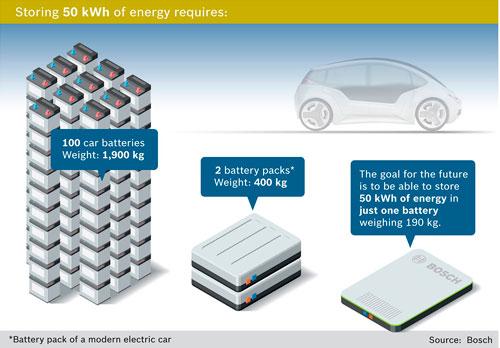

Continual research into improving the traction battery has seen wider and wider adoption of lithium-ion, which produces a much denser charge in a very much smaller package than traditional lead-acid batteries.

However, lithium-ion batteries need to be treated carefully by car designers as they are prone to heat build-up which requires complex cooling systems to prevent the possibility of vehicles bursting into flames. They are also costly to produce, and have a lower service life than, for instance, lead-acid batteries.

One interim solution is the development of the lithium-sulphur battery. Not only do these run much cooler than lithium-ion, thanks to the use of solid sulphur-based materials, but the batteries are also lighter, cost less to produce, and produce about four times the gravimetric energy density of lithium-ion technologies.

Without doubt the battery problem associated with electric vehicles is a continuing process of evolution.

The combination of electricity from renewable sources – especially in places such as New Zealand – combined with clean-running EVs, can lead to lower global emissions, and should make a significant contribution to cleaner air for all.

Now all we have to do is get the costs down.