In breaking news as we went to press, the New Zealand Transport Agency is proposing changes to the Low Volume Vehicle certification process to make it easier for commercial modifiers to obtain approval where they produce a series of identical vehicles – also known as “type certification”.

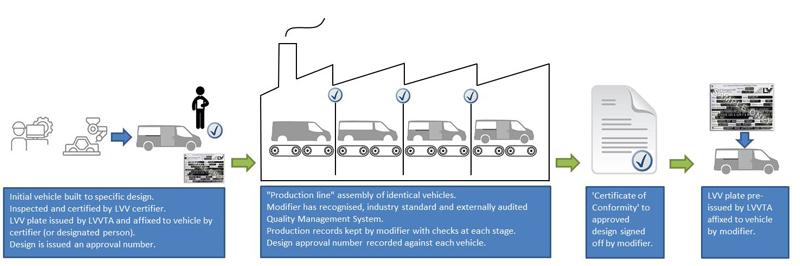

Essentially what the NZTA is saying is that approval must be obtained for the first vehicle – the blueprint, if you like – in the same way as currently, with an approved certifier watching every step of the way, then provided he has approved the process, subsequent vehicles can be built on a “production line” using the same process, with checks and balances in the form of production records of checks at each stage.

The benefits include:

- Increased efficiency as production can carry on continuously – there is no down-time in production while waiting for an LVV certifier to inspect each vehicle in stages. Stage inspections will be completed by the modifier.

- The cost of producing modified vehicles will be reduced as less LVV certifier involvement will be required.

- LVV plates will be able to be pre-issued to the modifier and fitted onsite, allowing vehicles to get on the road more quickly.

At the same time, to ensure safety is maintained the proposed process includes a number of criteria and checks.

- Commercial modifiers must meet a strict set of criteria, including the Transport Agency’s standard “fit and proper person” requirements.

- Commercial modifiers must be appointed by the Transport Agency and be required to perform to a high standard.

- Modifications will be made in a factory-like setting, with structured processes and quality controls.

- An externally-audited QMS system will ensure the production process has rigour and that good processes are being used.

- Modifiers must sign off the build of each vehicle at key points so that rigorous production records are, in turn ensuring inconsistencies can be picked up early and corrected.

- Keeping production records allows the Transport Agency to check that previously built vehicles adhered to the approved design.

- Auditing by the Transport Agency will ensure that the described build processes and approved type design are being followed.

The NZTA is carrying out a pilot process which started in late September and will continue through October 2016.

The pilot will be run with one commercial modifier who meets the eligibility criteria and is able to help the NZTA test how the proposed process will work in reality. The Transport Agency will work closely with the modifier as they carry out multiple modifications of an approved type, and confirm the checks and processes required to ensure all vehicles are being produced to the approved design.

After that, the Agency will assess the outcome of the pilot, along with feedback from a discussion document which has been circulated to interested parties, and make any adjustments required to the process, with the expectation of stating to allow type certification by late November 2016.