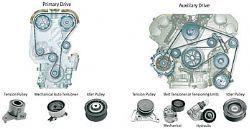

The Schaeffler Group and its brands LuK, INA and FAG stand for pronounced customer orientation, innovative force and maximum quality. The company INA was founded in 1946. Vehicle manufacturers throughout the world rely on application solutions developed by the German company. INA is a partner of both, the original equipment and the aftermarket sales businesses for passenger cars and commercial vehicles. INA is the market leader in supplying belt drive components to car manufacturers. In addition, INA is the worldwide technology leader in designing and manufacturing auto belt tensioning units for the accessory drive. With its comprehensive product range of 1.225 single belt tensioners and idlers, INA belt drive components are available for more than 10.000 different vehicle applications. The Business Unit Automotive Aftermarket at Schaeffler Group Automotive supplies the independent automotive aftermarket with original equipment parts for passenger cars, light commercial vehicles, trucks, busses and agricultural tractors. The product range for passenger cars comprises a large variety of INA belt drive single components, sets and kits. While the kit contains the belt and the according tensioners and idlers, the set comes without the belt. Belt Drive Components Belt drive systems in motor vehicles have to cope with ever growing tasks and loads. State-of-the-art engines – particularly diesel engines – generate extreme torques of up to 400Nm. Toothed belt, tension rollers and idlers must ensure reliable transmission of this force – throughout the entire service life of the vehicle. There are two different types of timing belt tensioners – manual and automatic belt tensioners. For manual belt tensioning units, the correct belt tension at ambient temperature is set manually according to the specifications of the manufacturer and needs to be checked in the specified service intervals and adjusted if required. Auto-tensioning units tighten the belt automatically during installation. An internal set of springs ensures that the belt tension remains almost unchanged throughout the entire service life by self-adjusting to temperature and load changes. Another benefit of an automatic tensioning unit consists in its ability to damp out belt vibration under all operating conditions of the belt drive. As a result, the belt tension can remain very low thus reducing noise emission whilst increasing service life. Things have also changed for the auxiliary drive. Whereas in the past only the alternator had to be driven, the accessory drive today includes a number of components for enhanced comfort, such as power steering pump or A/C compressor. Here, too, tension rollers and idler play a major role. Tension rollers and idlers are used for both the timing and accessory drives. Tension rollers transmit the force from the belt tensioner to the belt, thus ensuring constant belt tension. Idlers are used to change the belt routing according to the existing front end accessories or serve to stabilize the belt and to eliminate belt vibration in excessive strand lengths. Tension rollers and idlers consist of a steel or plastic pulley with integral single or double row deep groove ball bearing. The running surface can be either smooth or grooved. After mounting the roller, a protective plastic cover is snapped on the unit. Especially formed covers made of steel may also be used to protect the idler bearing. These are bolted to the idler. Benefits/advantages of tension rollers and idlers: • Ensure precise routing of the belt • Allow for individually designed and optimised belt drive layout • Are matched to the specific application • Reduced grease losses • Reduced noise emission during operation • Resistant to temperature and environmental influences • Knurlings ensure positive engagement between outer ring and plastic running pulley • Regular maintenance – a must A critical prerequisite for trouble-free operation of the timing belt drive or the accessory belt drive is the correct tension. A slipping poly V-belt can destroy the rollers of the front end accessories or cause the belt to tear. With a faulty power steering pump the vehicle can no longer be controlled. A faulty water pump results in the overheating of the engine - including all consequential damages. A torn accessory drive belt can also destroy the timing belt and result in an engine breakdown. How much a component is worn out varies for each vehicle but belt drive systems must operate under most demanding conditions. In an environment of excessive heat and dirt, continuous load changes as well as stop-and-go traffic, belt drive components are subject to extreme wear. This is why the service instructions and repair schedules specified by the manufacturer should always be adhered to. Unlike copied parts, INA manufactured tension rollers are equipped with special bearings which ensure long service life and therefore increased reliability and safety. For this reason, each workshop should only rely on INA products in order to avoid any consequential damage to the engine which may result from fitting copied tension rollers with built-in standard bearings. Furthermore, the complete tensioning unit should be replaced instead of just a single roller or damper as this may considerably reduce the service life of the complete tensioning system. Now available from the Business Unit Aftermarket at Schaeffler Group Automotive: the INA universal tool kit for professional repair and maintenance of belt drive components. The high-quality tools included in the kit do not only cover all current vehicle makes and models, but also older engine types. The kit comes with a detailed description of how and when each tool is to be used. Additionally available – a sturdy hard-shell case with special foam inserts to protect the kit components while they are not in use or during transportation. The purchase price of the complete set is less than the sum of its individual elements. The tool case’s contents at a glance: • Toothed belt tension roller dowel pin • Camshaft pulley holder • V-belt pulley holding tool • Holding wrench universal set • Camshaft pulley universal locking tool • Alternator wrench • Camshaft pulley extractor • Belt pulley extractor set • Crankshaft arresting pins • Flywheel locking pin All kit components are also available individually.

INA - The Brand of Choice for Engine Parts

INA - The Brand of Choice for Engine Parts

Motorsport

Sunday, 13 July 2008