Rather than just traditional cooling, automotive manufacturers now consider the overall thermal management of the powertrain in a more holistic way.

In reality this was always the case, but the main focus was in traditional cooling via the vehicles radiator. As engines become smaller in size and higher in specific power output, have less mass due to light weighting and tighter packaging and air flow as vehicles shrink and manufacturers look to minimise drag, then other options need to be included in the thermal management equation.

Emissions regulations require much tighter control of engine temperatures to minimise emissions (which are much higher when the engine is cold but conversely also increase if the engine gets too hot).

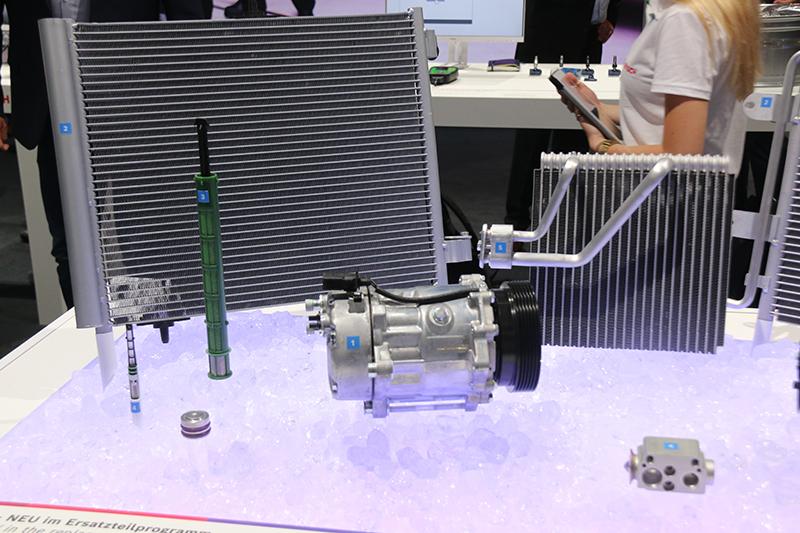

Rather than just an engine radiator, modern cars now have some or all of the following which are integrated into the thermal management: radiator, air conditioning condenser, transmission cooler, power steering cooler, intake air intercooler and associated fan(s) and pump(s).

The radiator and air conditioning condenser are usually mounted together and are supplied with air flow by the fan which may be electrically driven or driven by the engine via a fan belt and viscous clutch system. Sometimes the transmission cooler is integrated into the radiator (fluid to fluid) and sometimes has its own radiator (air to fluid).

To reduce power loss there is a trend for both the coolant pump and the fan to be electrically driven rather than belt driven, this also allows electronic control of the speed of the fan and pump rather than being linked to engine speed, which can increase cooling potential at lower engine speeds and decrease parasitic power loss at higher engine speeds.

EGR coolers – the new kid on the cooling block

To meet the new Euro 6 regulations. Especially for diesel engines, a new cooling system is being added to help control nitrogen oxide emissions by way of EGR (Exhaust Gas Recirculation) cooling. Some exhaust gas is extracted between the exhaust and the turbocharger and is cooled in an EGR cooler (usually water cooled) before being reintroduced to the intake reducing combustion temperature which reduces nitrogen oxide.

Intake air cooling

Also know as charge air cooling or intercooling. With most modern engines being turbocharged the intake air gets heated when compressed, Intercooling is a tried and tested procedure for increasing performance by cooling the air after it is compressed (usually in an air-air intercooler but sometimes using fluid from the cold side of the engine cooling system) to reduce the temperature and therefore increase the density. This also has benefits in terms of lowering the production of pollutants such as nitrogen oxides.