The drum brake is almost as old as the car itself. Many regard it as an old-fashioned product that is primarily associated with small cars of low performance engines. This may result in an oversight to the existing technical features of the drum brake technology itself, durability, robustness with environmental brake dust reductions. These main benefits of consideration together with further enhanced technological development is why automotive manufacturers should refocus on the future drum brake technology.

Traditional technology in modern cars – the closed system offers additional protection

Electric Vehicles in particular can benefit from drum brake technology due to the vehicle onboarded electrical power recuperation systems that are effectively retarding the vehicle during normal driving conditions to the extent that the brakes are rarely used, except for the instant or emergency case.

Due to the infrequent usage of the traditional disc brake system, they become more susceptible to corrosion (rust film) buildup, that may cause less of a braking force after an extended time of non-actuation, however they must be 100 percent instantly available when required.

The drum brake technology is completely enclosed within a housing system that offers protection to the mechanical mechanism and brake surfaces against corrosive elements such as rain and salts. The enclosed housing system of the drum brake allows the internal friction shoe, pully and springs to operate reliably and perform to the required and relevant residual braking torque force application, and further reliability for the instant and emergency case application.

Particulate emission reduced through closed design

The drum brake offers even further attractions, the environmental particulate emissions are vastly reduced when compared to the traditional disc brake system technology, that will bring upcoming decisive decisions to comply with increasingly stricter environmental requirements.

While combustion engines have had to comply with increasingly stringent emission limits in recent years, the focus has now widened to include foundation brakes. The fine brake dust generated from the brake system can have far-reaching adverse effects on human health, depending on the size of the particles emitted. Experts expect stricter legal requirements from the EU Commission by 2025 at the latest.

Drum brake technology takes advantage of the enclosed housing system, allowing the brake dust particulates to be accumulated within the enclosed system that can be collected and disposed in a controlled manner that protects the environment.

Possible uses of the drum brake – EPB-Si as a patented drum brake solution

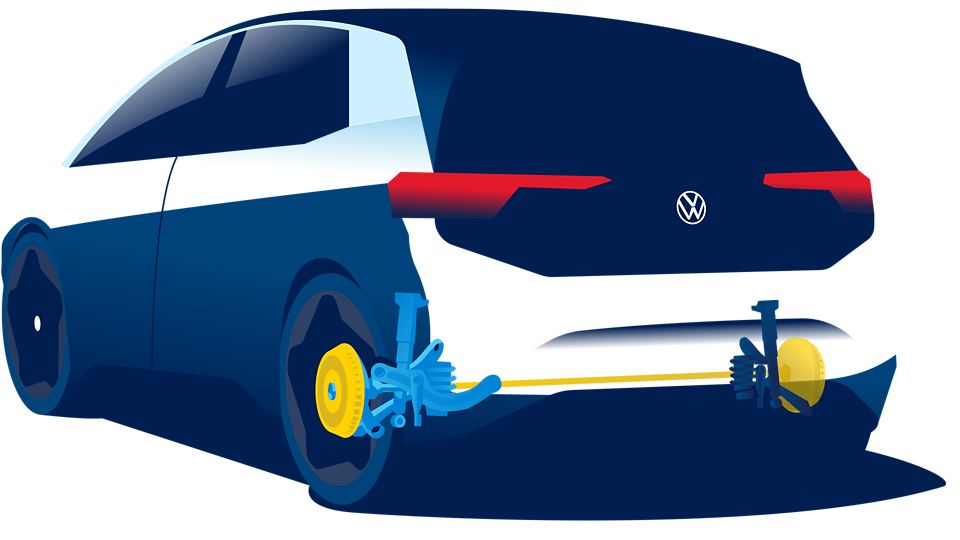

The “EPB-Si” drum brake on the rear axle is already functioning perfectly, as Volkswagen and Continental have shown with VW ID.3 and VW ID.4. The electric cars are fitted with a set of drum brakes on the rear axle. With the EPB-Si, Continental is manufacturing and supplying a patented drum brake solution that is particularly suitable for more sustainable braking. It eliminates corrosion, reduces particulate emissions – and the electric parking brake function is also integrated into the patented design.

Installing drum brakes on the front axle is also thoroughly practicable. The duo-servo principle achieves high braking torque at low actuation forces; the self-amplifying effect of this functional principle can be positively exploited. This makes the front axle drum brake an ideal module for the next generation of dry-operated foundation brakes. Continental is preparing for a wide range of customer inquiries and further developing a diverse portfolio of foundation brakes.

Conclusion

In the light of this mixture of system properties, the drum brake is an attractive option not only for the rear axle of electric vehicles, but also for the front axle of vehicles generally, depending on the vehicle segment and requirements.

Courtesy Continental