As we drive our cars and trucks doing daily tasks, most of us now enjoy similar comfort levels that we have in our homes. With a simple push of a button we can change our environment from heating to cooling, then back again without even considering how this magic occurs. Today air conditioning comes as standard equipment in most cars and trucks. In the early days motor cars were viewed as “horseless carriages”, so manufacturers had not yet considered improving driver comfort including environmental factors such as air quality. How-ever as the turn of the 20th century rolled over, a gradual move to closed-body vehicles became standard and automotive innovators started to look at the best way to develop an effective automotive cooling / heating system. Even then the first functioning automotive air conditioning system wasn’t developed until 1939 by Packard.

Since the 1940’s automotive air conditioning systems have undergone extensive development and refinement. Features, such as automatic temperature control and improvements to overall reliability, have compounded the complexity of the air conditioning system bringing the days of “do-it-yourself” repair to a thing of the past.

In addition to complicated A/C systems, we have environmental regulations that regulate the automotive industry, such as recharging the system with refrigerant R12 which most of know as Freon (Freon was the trading name for the refrigerant R-12, which was manufactured by DuPont). Environmental studies proved the damaging effects of this type of refrigerant to our ozone layer, and today its manufacture has been banned by most countries around the world. The Montreal Protocol was a landmark treaty agreement that was introduced on the 26th of August 1987 to limit the production and use of any chemicals known to deplete the ozone layer.

Now, more than ever, automotive technicians must comply to environmental legislation. The A/C repairer is required to be certified to remove and re-gas refrigerant whilst repairing any A/C System, and now any workshop also incurs the high cost of purchasing expensive dedicated equipment that insures the capture of these ozone depleting chemicals. Simply put, anyone involved in A/C servicing and repairs must now invest considerably in training, certification and specialist A/C equipment to repair your vehicle – this has become a specialist trade for more advanced A/C repairs. Basic knowledge of your air conditioning system is important as an owner of the vehicle as this will allow an informed decision on your repair options. But general automotive repairers are facing the reality that specialist A/C technicians are part of the automotive landscape as with other sub-specialist automotive trades.

Should a major problem arise in your classic vehicle that used to have R12 (Freon) in the A/C system, you may encounter terminology words such as “upgrade” and “alternative refrigerant”. There are options of “retrofitting”, as opposed to merely repairing and recharging with R12. Retrofitting involves making the necessary changes to your system, which will allow it to use the industry accepted, “environmentally friendly” refrigerant of the present. Modern refrigerants have higher operating pressures, therefore, depending on age, may need stronger components to counter the high pressure.

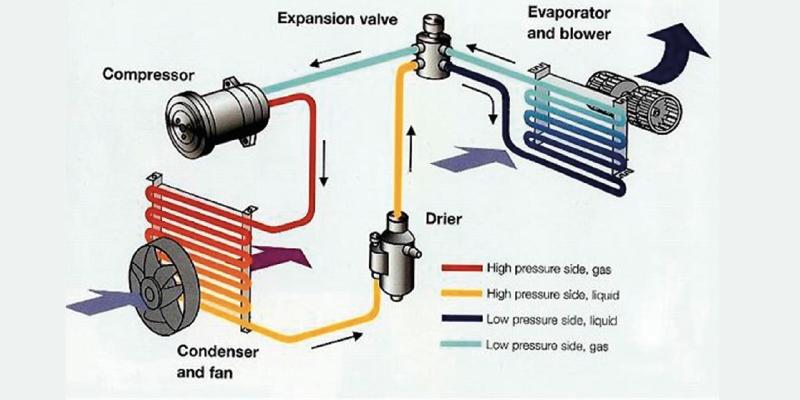

Vehicles of today are found to have various configurations of air conditioning systems. While most types of A/C systems differ from each other in exact design, the concept and general layout are very similar to one another.

The most common components which make up these automotive systems are the following:

Compressor. Generally referred to

as the heart of the system, the compressor is a belt driven pump that

is fastened to the engine. It’s responsible for compressing and transferring refrigerant gas.

Condenser. This is where heat dissipation occurs. The condenser in many cases, will have much the same appearance as the radiator in your car as the two have very similar functions.

Evaporator. Located inside the vehicle, the evaporator serves as the heat absorption component. The evaporator provides several functions. Its primary duty is to remove heat from the inside of your vehicle.

Orifice tube. Can be found in most GM and Ford models and located in the inlet tube of the evaporator, or in the liquid line, somewhere between the outlet of the condenser and the inlet of the evaporator. Orifice tubes are used in systems that don’t use expansion valves.

Thermal expansion valve. Another common type of refrigerant regulator is the thermal expansion valve, or TXV. Commonly used on import and aftermarket systems. This type of valve can sense both temperature and pressure and is very efficient at regulating refrigerant flow to the evaporator.

Receiver-drier. The receiver-drier is used on the high side of systems that use a thermal expansion valve. The primary function of the receiver-drier is to separate gas and liquid. The secondary purpose is to remove moisture and filter out dirt.

Accumulator. Accumulators are used on systems that accommodate an orifice tube to meter refrigerants into the evaporator. It is connected directly to the evaporator outlet and stores excess liquid refrigerant.

Today, as efficiency and environmental concerns become a prime focus, the new primary refrigerant is HFO-1234yf – Hydrofluoroolefin which has a low-GWP (Global Warming Potential). It is intended as total replacement for R-134a which is considered “not” to be that environmentally friendly, so as with most technology we will see HFO-1234yf used in most new vehicles air conditioning systems in the automotive industry going forward. Today we have already seen many countries take steps to phase out and even ban R134a. If you work in the automotive industry, you’ve probably already seen the increase in A/C systems using 1234yf.

Launch Tech NZ, a division of Quantum mechanics limited, has a range of diagnostic equipment that can assist with most A/C repairs and servicing to most vehicle makes and models in New Zealand.

Contact: Launch Tech NZ

Phone: 0508 42 88 66, Email: support@launchnz.co.nz

For Launch sales, support and repairs.

Quick contact Vince Phone: 021 241 4885.