Courtesy of Brembo Brakes SPA

Everything evolves, including the cars’ braking systems.

Nowadays we are on the brink of a revolution as we are going from a hydraulic system to an electric one that will be in lock-step with the vehicles of the future. Brembo is ready to play a leading role for what promises to be a real transition for the cars’ braking system. For nearly two decades Brembo has been focused on engineering a complete solution for this transportation revolution.

This places Brembo in a leadership position, ready to take advantage of all the opportunities of a world that is pursuing more a revolution than evolution, just think of electric vehicles, but also autonomous ones.

Since 2001 the investment in R&D activities for the electric braking systems or brake-by-wire, as the insiders define it, has been growing. This is the driving force that will open the doors to great changes for braking systems and that makes one say that the “brake of the future” is about to see the light. It’s in-step with the progression toward mechatronics and the forward movement of vehicles being developed that are more efficient, interconnected and intelligent.

Energy recovery reduces both weight and emissions, which have become increasingly important to society and manufacturers. The braking system of the future can play a decisive role for both of these factors.

For example, today the automotive world has a great focus on energy and the braking system can prove to be a source from which much of it is can be extracted. Brembo is very much engaged in brake-by-wire, not only with regards to the road going cars, but also in racing cars. This technology, electrical braking systems, has been used under the most strenuous conditions in Formula 1 since 2014.

But how does Brembo’s brake-by-wire system work? What are the differences compared to a traditional system and, above all, what are the advantages?

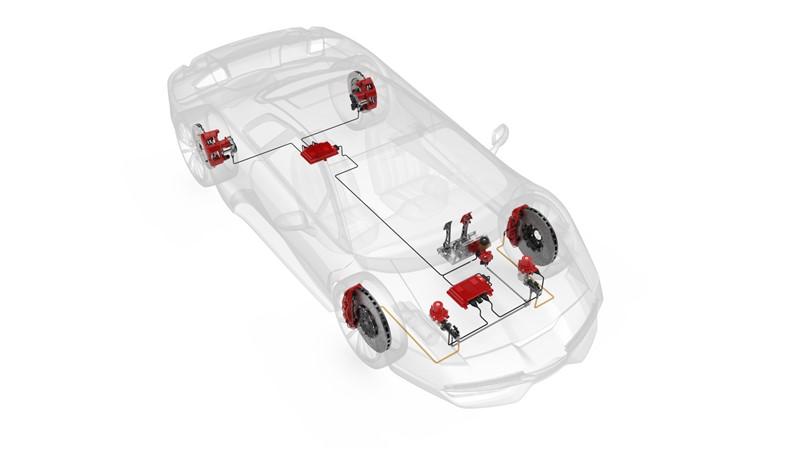

The Brembo brake-by-wire system is operated by pressing the brake pedal, just as for a traditional hydraulic system, at this point the pedal’s travel sensor detects the pedals position and sends the information to the control unit at the exact same time the pedal returns the braking feel of a traditional hydraulic system to the driver.

At the same time, the electronic control unit processes the signal it has received from the pedal sensor and sends the command to the actuators. The electromechanical hydraulic actuator converts the electrical impulse received from the control unit into the caliper’s hydraulic pressure/clamping force to slow or stop the vehicle.

The caliper that is operated by the actuator can either be a brake caliper with a traditional hydraulic connection or an electromechanical caliper managed directly by the control unit that converts the electrical energy it receives into braking force. The force is transmitted through brake pads directly to a cast iron, steel or carbon-ceramic brake disc.

The Brembo brake-by-wire braking system is designed and manufactured according to all the safety standards prescribed by law and by the automotive industry (e.g., homologation and ISO 26262).

Should the system experience a malfunction, it will detect any anomalies and bypass the non-functioning element. The architecture of the actuators distributed among the wheels enables the Brembo brake-by-wire braking system to automatically reconfigure itself should a single device malfunction. The system will continue to operate through the devices that are functioning, guaranteeing deceleration that is in any case superior to what is required by law (2.44 m/s2). This distinct feature of the Brembo brake-by-wire system ensures the braking performance needs of drivers are met even in the event of accidental malfunction.

In the event of a total loss of electricity, the conventional hydraulic safety system will take over for the brake-by-wire system enabling the braking system to operate on the front wheels, thus meeting the relevant legislation for secondary braking.

There are many advantages that an electric brake system such as this can provide.

The advantages for drivers are greater safety, comfort and customisation.

Let’s start from the drivers and from a non-negotiable value such as safety. The electric brake system allows a significant reduction in stopping distances compared to a traditional system.

Specifically, Brembo’s brake-by-wire system, in its latest evolution has made a great leap forward in response time, surpassing the old standard of 300-500 milliseconds to 100 milliseconds! Just to better understand what these numbers mean, bear in mind that in 300 milliseconds a vehicle travelling at 120 km/h will cover 11 metres and that the blink of an eye takes approximately 250 milliseconds.

The brakes speed of response is vital, because if an immediate stop is the goal, then it‘s only thanks to the system’s greater reactivity that several feet of stopping distance can be saved. This, in regard to safety, can prove to be decisive. Therefore, speed of response means safety.

In addition to the advantages in terms of responsiveness (greater safety and increased braking performance) there are also many advantages for driver comfort.

In fact, the driver, thanks to the brake-by-wire system, will be able to customise both the braking force as well as the pedal‘s response. For example, drivers will be able to choose between different braking patterns, depending on their personal preferences and their driving style (e.g. sport, track, comfort) and, similarly, will be able to choose between different pedal response patterns according to their preferences.

In respect to comfort, one of the main advantages of Brembo’s brake-by-wire system is the stability of braking, regardless of the load. In fact, the brake system will automatically adapt to the vehicle‘s load conditions, keeping the braking space constant. In addition, a further feature of driving comfort due to the brake-by-wire system is provided by the transition from dissipative braking to regenerative braking that is smooth and imperceptible for the driver.

Venturing further, beyond the integration of the two braking types, regenerative and dissipative, which is known as “blending”, this could lead to autonomous braking, braking without even using the brake pedal!

When the accelerator is released, the brake-by-wire system performs an automatic compensation of the engine braking or of the regenerative braking in order to achieve a stable deceleration that allows the stopping or controlling of the vehicle during normal road use both in town and on the highway.

For emergency braking or for more sporty driving or a track day, operating the brake pedal is required as it is today.

The advantages for drivers are also important on an economic level. A greater integration with the regenerative braking system, thanks to using the brake-by-wire system, means less wear and this can lead to lower disk and pad wear.

Even the brake fluid reduction is not negligible, when compared to a standard braking system, this involves a reduction of maintenance and operating and costs. Furthermore, the maintenance of discs and pads can be synchronised with the vehicle‘s general maintenance programme thanks to more controlled wear.

The advantages for vehicle manufacturers:

The brake-by-wire system’s advantages are not limited only to the benefits in terms of safety, performance and comfort for the driver. In fact, brake system electrification opens the doors to a greater interaction with other components. Just think of active braking when releasing the accelerator or of using a single brake for each wheel as a differential or stabilising function for the vehicle.

Thanks to the brake-by-wire system, the manufacturers can think of repositioning the components and also rethink the vehicle’s architecture in favour of space, safety, mass, and performance. In the future vehicles will be radically different from what is currently on the road. The brake-by-wire system offers manufacturers greater flexibility to optimise weight distribution and overall vehicle performance.

An eco-friendlier system

Brembo’s evolving brake-by-wire system looks like the ideal solution for present cars as well as for those of the future.

Brake-by-wire integration with the energy recovery system works seamlessly to reduce the electric or hybrid vehicles battery charging phase.

In addition, a great advantage of the brake-by-wire system for cars with a traditional combustion engine is a further reduction of the phenomenon called “residual torque”.

Residual torque is an intrinsic and unwanted friction between the disc and the pads outside the braking phase, this causes, although imperceptibly, the vehicle to brake and to increase fuel consumption and therefore the emissions.

This phenomenon is already minimised by Brembo‘s traditional fixed hydraulic calipers but it‘s further reduced thanks to the brake-by-wire system.

This in fact allows a CO2 emission reduction or an increase of the electric cars’ driving range. When looking into the future, the new components will allow a better integration thanks to sensors, the eyes and ears of the driverless vehicle.

Longer duration also means a greater focus on the environment and, again, the environment will benefit from the removal of fluids and reduced parts count.

A look at the future

The brake-by-wire system is also designed to integrate itself with the regenerative braking and driver-assistance systems. Therefore, it’s not difficult to imagine that a day will come when the cars brake on their own as the auto-pilot will tell them to do so (as is already happening now with electric steering).

The brake-by-wire system clearly offers additional advantages with respect to conventional vehicles as well as being also definitely so versatile that any scenario can be opened up.