Given how vital a vehicle’s braking system is to the safety of the driver, occupants and other road users, it’s critical that all aspects of brake servicing, maintenance, repair and replacement is carried out with care.

The following are a few points to consider when undertaking a brake job, whether changing brake pads, disc brake rotors, drums and shoes, or doing more complex component rebuilds, often it’s the small things that can be overlooked.

Inspect thoroughly

Although the primary focus might be to fit a new set of pads or disc brake rotors, while the wheels are off, the opportunity should be taken to thoroughly inspect the entire braking system and other hard to access components. This could include sighting and feeling the brake hoses for cracks, deformities, or connector corrosion.

While doing this, if the rotor hubs are showing signs of corrosion, now’s the perfect chance to clean them. Surface rust can form at the hub face where the rotor sits, and if the corrosion isn’t removed, once the new rotor is fitted, it may not sit properly – this could result in vibration when driving. Cleaning the rotor hub is a quick and easy job using sandpaper, steel wool or a wire brush.

Also take this opportunity to inspect wheel stud threads to ensure they’re free of corrosion – if they’re a bit rusty, tackle them with a wire brush, this will ensure that the nuts can easily be tightened and loosened when required. Once cleaned, if the nuts don’t turn smoothly inspect to make sure the studs have not been cross threaded. Cross threading will impact how well the nuts (and wheel) can be tightened. Studs will need to be replaced if damaged.

For newer vehicles with ABS, check the ABS sensor. This system works by reading imprints in the rotor, so it’s important that this sensor is clean. The majority of ABS sensors are located at the wheel hub, meaning they’re prone to dirt and road grime. If they do look dirty, clean with Bendix Cleanup.

Check lubrication

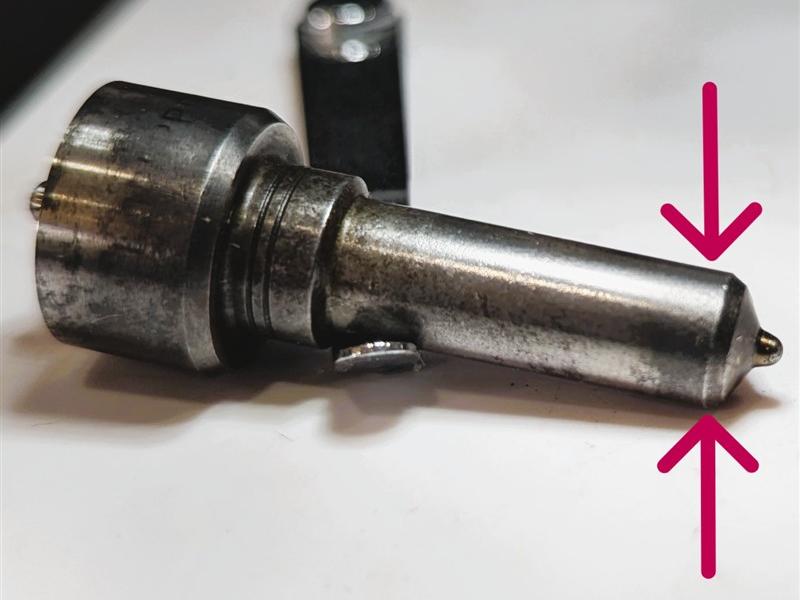

Sliding pins and boots are other items that can sometimes be overlooked. The sliding pins play a critical role in the brake caliper’s operation and should slide freely, if they’re stiff this may result in the caliper not fully releasing which can cause a vehicle to pull in the direction of the engaged rotor. As well as being dangerous, this can increase fuel consumption.

If the sliding pins and boots appear damaged, they should be replaced. If the sliding pins look serviceable, they may just need lubricating which is a simple job using brake lube such as Bendix Ceramasil.

Bedding in (not needed with Bendix)

Depending on the brake pads chosen, ‘bedding in’ may be needed – during this process dirt and debris from the rotor surface is removed and a thick layer of brake pad compound is transferred to the surface of the rotor. Failing to undertake this procedure – which involves a series of warm-up and then aggressive braking applications – can result in uneven pad depositions on the rotor surface and will feel like the rotors are warped.

To avoid this, select Bendix brake pads. Bendix pads feature a ‘Blue Titanium Stripe’, which is designed to rapidly mate with the rotor when brakes are first applied. Full braking performance is achieved instantly, eliminating the need for you to bed in, saving considerable time.

Don’t forget the brake fluid

Brake fluid plays an important role in a vehicle’s braking system but is often forgotten. It ensures that braking force from the pedal and brake master cylinder is transferred to the brake calipers, to bring the vehicle safely to a standstill. If replacing worn brake pads, the brakes should then be bled to ensure there’s no air trapped in the brake lines.

The brake fluid should be periodically monitored and changed in keeping with recommendations in the vehicle’s service manual. For more detailed information about the role of brake fluid and which one to choose, visit Bendix feature article: Bendix explains brake fluid699.

With these additional boxes ticked off the brake job checklist, the vehicle should be good to go for many more kilometres.

https://www.bendix.com.au/bendix-news/bendix-shares-common-brake-job-oversights