With the world’s first public crash test involving two fully electric vehicles, Mercedes-Benz is going above and beyond not only the legal requirements but also those of the ratings industry. Euro NCAP stipulates a frontal impact test using a 1,400 kg trolley with an aluminium honeycomb barrier replicating the front of another vehicle. In accordance with the specifications, the test vehicle and the trolley collide with an overlap and at a speed of 50 km/h.

Mercedes-Benz, however, used two real vehicles, an EQA and an EQS SUV, which are significantly heavier at around 2.2 and three tonnes respectively. In addition, both models were faster, each going 56 km/h, which meant that the overall crash energy was considerably higher than required by law. The vehicles’ extensive deformation following the collision may seem alarming to the non-expert. For the Mercedes-Benz engineers, however, it shows that the vehicles were able to effectively absorb the energy of the collision by deforming.

As a result, the passenger safety cell of both electric models remained intact and the doors could still be opened. In an emergency, this would make it possible for occupants to exit the vehicle on their own or for first responders and rescue personnel to reach them. The high-voltage system in the EQA and the EQS SUV switched off automatically during the collision.

Dummy readings indicate risk of occupant injury

The EQA and the EQS SUV each carried two adult dummies – a total of three females and one male. Analysis of the up to 150 measuring points per dummy indicate a low risk of serious to fatal injury. This means that the defined crumple zones and advanced restraint systems in both vehicles offer very good protection potential for the occupants in a crash of this severity. All safety equipment, such as airbags and belt tensioners with belt force limiters, worked as intended.

The crash test thus confirmed the results that the engineers had previously calculated in numerous computer simulations. Real-life vehicle testing always also serves as a final comparison with the simulations. Furthermore, the crash test clearly shows that compatibility (i.e. the interaction of the deformation structures of different vehicles involved in an accident) is part of the safety requirements for Mercedes-Benz cars.

Female dummies in the driver’s seat

Another focus of the crash test was the type of dummy that the safety experts placed in the driver’s seat of both vehicles – the Hybrid III 5th Percentile Female, which is the female dummy currently used in the automotive industry for frontal collision tests. It corresponds to a woman of approximately 1.5 metres tall and weighing around 49 kilograms. According to the underlying statistics, only five percent of women worldwide are smaller or lighter. For many years, Mercedes-Benz has used frontal crash tests with fifth percentile female dummies[1] in the front seat to design its protection systems for the widest possible range of customers. Ratings by consumer protection associations as well as various legal requirements worldwide now include specifications for testing with fifth percentile female dummies. Another fifth percentile female was a passenger in the EQA. In the passenger seat of the EQS SUV was a Hybrid III 50th Percentile dummy, representing a 78-kilogram male of average height.

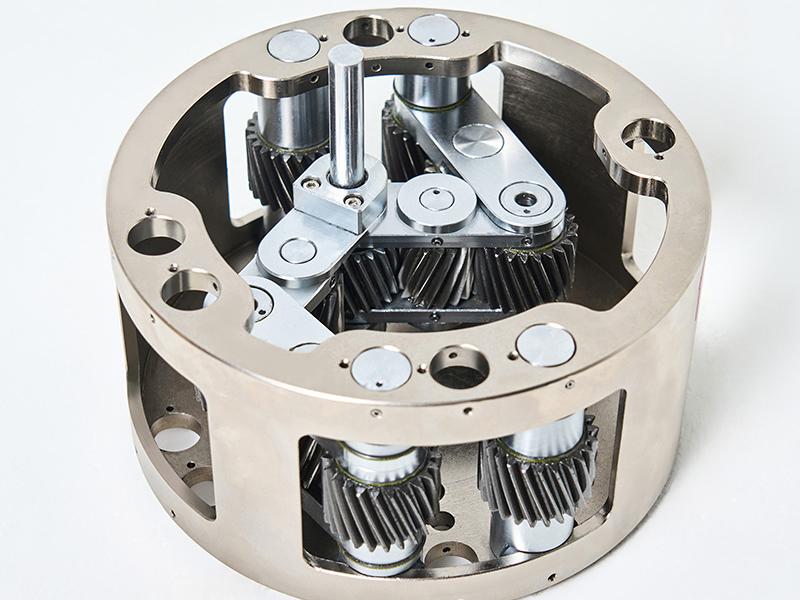

Special high-voltage safety concept

Mercedes-Benz has developed a multi-stage high-voltage protection concept for its electric vehicles. The system has eight key elements to ensure the safety of the battery and all components with a voltage above 60 volts. Examples include separate positive and negative wiring and a self-monitoring high-voltage system that automatically switches off in the event of a serious collision. In many cases, the company’s high internal safety standards exceed the legal requirements or those of consumer protection organisations. Mercedes‑Benz has impressively demonstrated this once again with the latest crash test.

The Technology Centre for Vehicle Safety is one of the most modern in the world

Since 2016, Mercedes-Benz has been conducting crash tests at the new Group-owned Technology Centre for Vehicle Safety in Sindelfingen. The test centre is one of the largest and most modern of its kind in the world. It has three highly flexible crash lanes leading into a large, support-free area measuring over 8,000 square metres (90 m × 90 m). Its capacity is also impressive: In Sindelfingen alone, Mercedes-Benz conducts up to 900 crash tests and 1,700 sled tests every year.