Those of you who have watched Monty Python will have heard of the mythical “Holy Grail”, which has never been found - but how’s about motoring’s Holy Grail, the wonder of a variable compression ratio engine? John Oxley reports on how Nissan seems to have achieved this in its latest offering.

It’s been said that the Holy Grail of automotive engineering is a variable compression ratio engine, which will give the best of both low and high compression engines with none of the disadvantages of either. More power, better fuel economy, fewer emissions, especially carbon dioxide – these are all part of what the designers are looking for in their bid to keep the internal combustion engine relevant.

With the buzz around electric power at the moment, why?

Simply put, a bucket of petrol produces more power than a whole carload of batteries, it’s easier for the user to replace the energy, and it’s a lot less expensive to make and to buy a petrol-powered car than an EV.

Yes, in the future batteries will get smaller and denser, more electricity will be generated from renewable sources, and the world will become electrified. But in the meantime, we have to work with what we’ve got.

Most of you reading this will know the basics, so I’m not going to bore you with minor stuff. But we all know that maximum torque is generated from high compression (hence the use of forced induction such as turbo-charging or supercharging on modern engines), but the problem is that in low load conditions a high compression engine can pre-detonate, in other words the fuel starts to burn without ignition from the spark plug, resulting in an inefficient burn pattern and fuel wastage.

Having said that, Mazda’s Skyactiv engines manage to use high compression ratios (14:1) with improved driveability and high efficiency by extensive use of knock-resistant technologies

Although variable compression ratio engines using mechanical connections to change the compression ratio, have been made in laboratories, until now they have been ruled out as being too complex for a production engine.

That said, the Atkinson Cycle engine, much-loved in petrol engines in hybrid vehicles, and these days in some higher-output engines such as Lexus’s 200T turbo motor (which switches between ordinary Otto Cycle and Atkinson Cycle according to the load), produces a variable compression ratio effect by keeping the inlet valve open longer (effectively reducing the compression ratio) or closing it sooner (to increase the compression ratio).

However, now Nissan has taken the whole bull by the horns and announced a full mechanically-operated variable compression ratio engine that, say some pundits, may well challenge the diesel engine for efficiency without the latter’s emissions issues in terms of NOx and particulates.

The new engine will be unveiled first at the Paris Motor Show next month in the next-generation Infiniti QX50 SUV, a car which we don’t currently get in New Zealand, but if it’s as good as Nissan says, it won’t be long before it spreads throughout the Nissan world – and by definition that includes Renault, too, making it a pretty big playing field.

The engine is a 2-litre turbo-charged four cylinder, dubbed VC-T (variable compression turbocharged), and Nissan says it will allow the compression ratio to be dynamically altered between 8:1 and 14:1.

The low compression “mode” is used during periods of high turbo boost under power to prevent detonation (knock), while the high compression mode is used to optimise torque and improve economy. And compression ratio can be changed everywhere in between, according to the engine’s needs. The engine can also operate in Atkinson mode during low load for even better efficiency.

Nissan says the new engine has been more than 20 years in development, and boasts that it represents a major breakthrough in internal combustion powertrain technology.

Says Roland Krueger, president of Infiniti Motor Company: “VC-T technology is a step change for Infiniti. It is a revolutionary next-step in optimising the efficiency of the internal combustion engine. This technological breakthrough delivers the power of a high-performance 2-litre turbo petrol engine with a high level of efficiency at the same time.”

He says the VC-T technology delivers multiple customer benefits, including significantly reduced fuel consumption and emissions, greatly reduced noise and vibration levels; it is also lighter and more compact than comparable conventional engines.

The good news is that, although it is more complex than most petrol engines, the VC-T is, says Nissan, cheaper to build than modern turbo-diesel engines, while matching them in torque.

How does it work?

Infiniti has patented more than 300 new technologies specifically designed for application in the new VC-T engine. Here’s how it works:

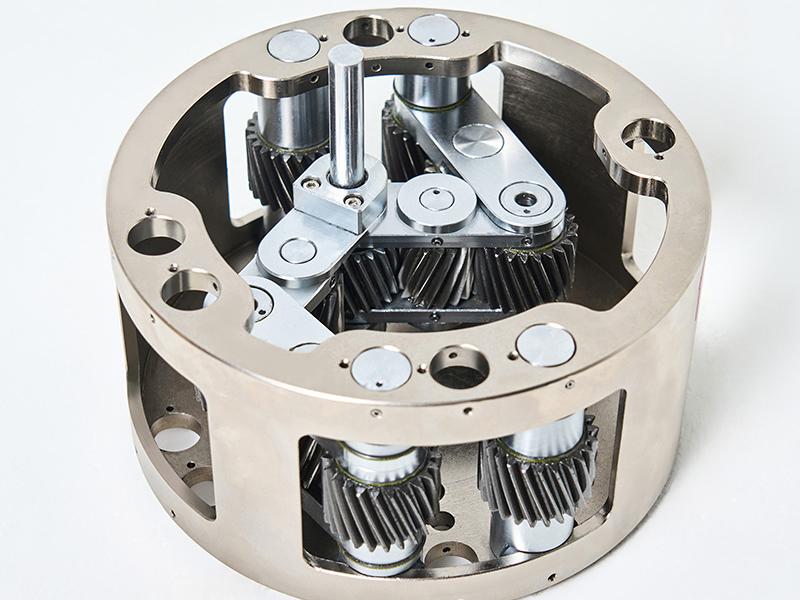

Infiniti has created what it calls a “Harmonic Drive”, driving a control arm. As the Harmonic Drive actuator rotates, a control shaft at the base of the engine also rotates, and moves a multi-link within the engine.

Changing the multi-link angle adjusts the top-dead-centre of the pistons, and so the compression ratio. The engine uses individual cylinder ignition timing control and valve timing for high-precision control over combustion characteristics

Electronic valve timing control is used for the fuel intake valves, contributing to more responsive acceleration, and enabling greater fuel economy under Atkinson cycle combustion conditions; the exhaust valves rely on conventional hydraulic valve timing control.

The VC-T employs multi-point injection (MPI) and direct injection (GDI), balancing efficiency and power in all driving conditions.

An integrated exhaust manifold is built into the cylinder head to improve packaging, performance and efficiency, and the VC-T employs an electronically-controlled wastegate actuator to maintain turbocharger boost pressure.

The VC-T engine also uses Infiniti’s low-friction “mirror bore coating” technology to reduce friction.

Nissan says the VC-T is a smooth-running in-line four-cylinder engine, due to the minimal lateral stroke forces from the pistons on the cylinder walls, and requires no balance shafts at the base of the engine; Nissan says conventional four-cylinder engines require two to minimise vibrations

Power output: this will be revealed at the show (they have to hold something back for effect I suppose), but Nissan says the VC-T engine’s intrinsic smoothness gives it similar NVH characteristics to a traditional V6 engine.

Given the power output of Ford’s EcoBoost motors, we would expect the VC-T would at least outperform them to be significant, which means high end V6 power and torque, while challenging diesel efficiency would mean looking at really low economy figures; less than 6L/100km in the QX50 to better figures being produced by Jaguar’s Ingenium turbo-diesels..